The chemical manufacturing industry is always striving for new ideas and technology to help us explore new avenues of study and production. We work hard to find innovations that transform traditional processes, making them more efficient, sustainable, and cost-effective. Capital Resin Corporation is always looking for the next big thing, so here are four emerging technologies and trends in chemical manufacturing that you should know.

Automation and AI Integration

Automation and artificial intelligence (AI) are revolutionizing chemical manufacturing by enhancing efficiency and precision. Automated systems can perform repetitive tasks more accurately, reducing human error and increasing productivity.

AI algorithms analyze vast amounts of data to optimize processes, predict maintenance needs, and improve product quality. The Industrial Internet of Things (IIoT) is working to transform chemical plants into smart, connected facilities with far more reach and capabilities.

Sustainable and Green Chemistry

Industries are always looking for the next big advancements in sustainability and green options. Green chemistry aims to design products and processes that reduce or eliminate hazardous substances. This approach minimizes environmental impact and enhances safety and compliance with regulatory standards. Chemical manufacturers can use innovative processes such as biorefining using renewable resources to produce chemicals and materials, reducing their dependence on fossil fuels.

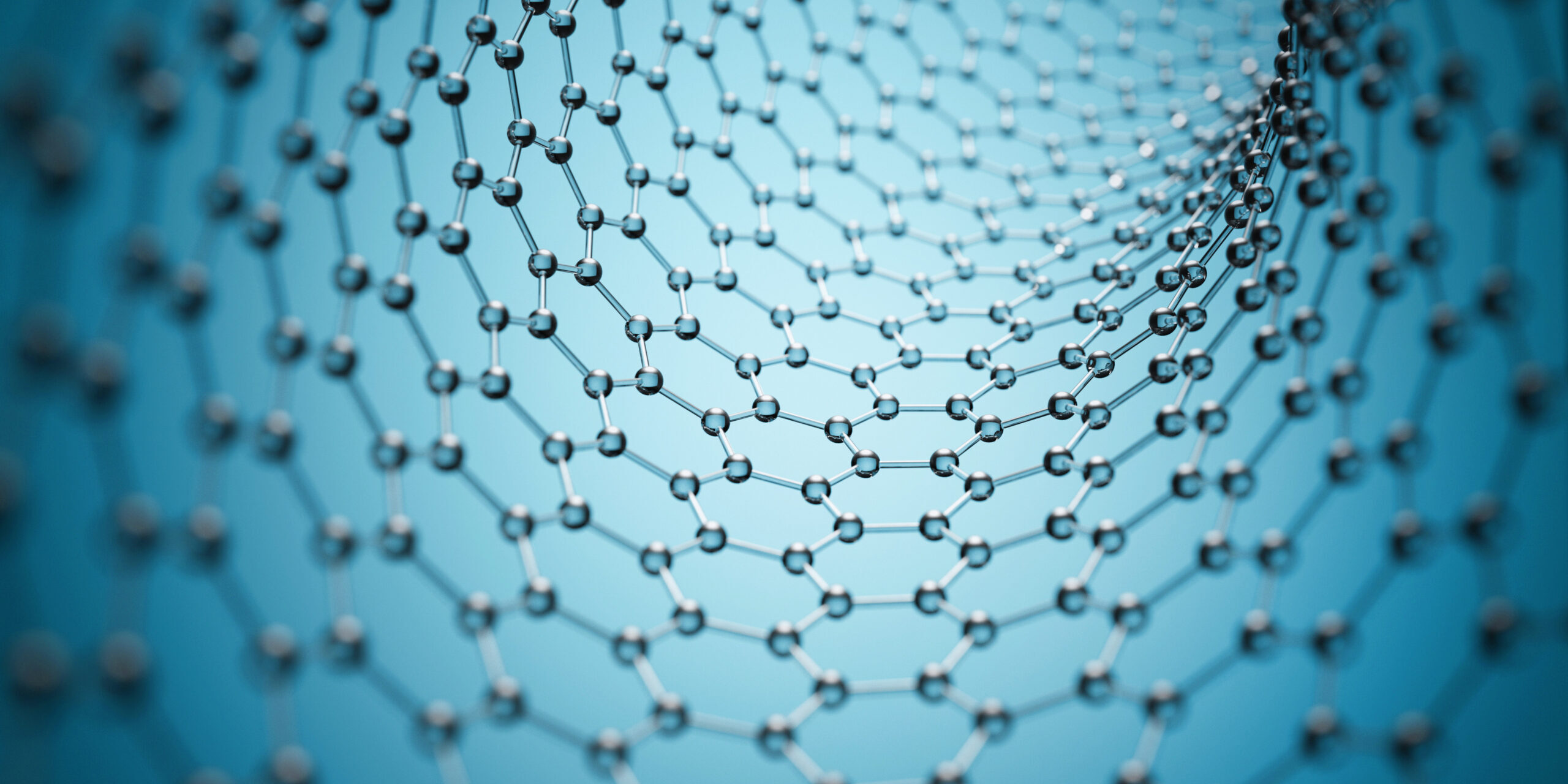

Advanced Materials and Nanotechnology

Nanotechnology isn’t a new idea, but the advanced materials and operations that we use with it are some of the biggest emerging technologies and trends in chemical manufacturing. Nanomaterials have unique properties that we can use to create innovative products with enhanced performance characteristics.

Industries use these materials in various applications, from coatings and catalysts to drug delivery systems. Furthermore, developments in advanced materials are also driving the development of sustainable packaging options to reduce plastic waste.

Digitalization and Data Analytics

Digitalization is transforming chemical manufacturing by harnessing the power of data analytics. Implementing smart manufacturing technologies allows for real-time monitoring and control of processes, increasing efficiency and reducing waste.

Chemical manufacturers can use data analytics tools to identify patterns and trends, providing valuable insights for decision-making and process optimization. As the industry moves toward a more data-driven approach, we’ll see more demand for chemical engineers with strong digital skills.

Capital Resin Corporation always strives to utilize advanced technologies to drive innovation in the chemical manufacturing industry. Collaborate with us in research and product development to take your projects to the next level. Contact us today to learn how our expertise and state-of-the-art technologies can help bring your vision to life.