Thanks to the efficiency, quality, and cost-effectiveness of custom chemical manufacturing, better known as toll processing, outsourcing to these chemical manufacturers has become a vital aspect of many fields, including the pharmaceutical, insulation, and even agricultural industries. While it’s clear that partnering with them is the most business-savvy choice, how much do these businesses understand about the process? Let’s talk about custom toll processing within the chemical industry.

Defining Toll Manufacturing

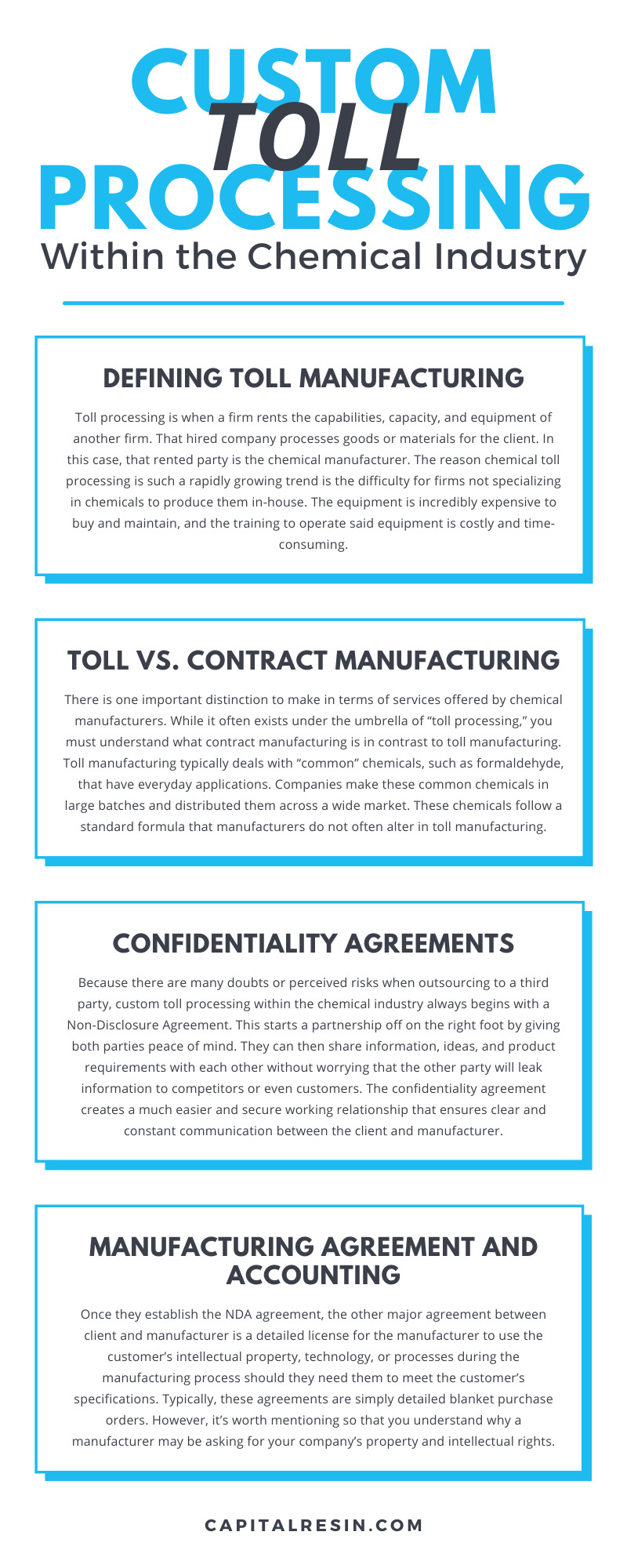

Toll processing is when a firm rents the capabilities, capacity, and equipment of another firm. That hired company processes goods or materials for the client. In this case, that rented party is the chemical manufacturer. The reason chemical toll processing is such a rapidly growing trend is the difficulty for firms not specializing in chemicals to produce them in-house. The equipment is incredibly expensive to buy and maintain, and the training to operate said equipment is costly and time-consuming. Moreover, if chemical manufacturing isn’t their exclusive focus, they can rarely produce a final product of the same quality that professional chemical manufacturers can provide.

Furthermore, toll processing is flexible. Manufacturers can arrange short, medium, and long-term processes, for example. They can then design the chemical manufacturing process around their needs to ensure they’re getting the best. For these reasons, it’s easy to see why outsourcing chemical production is such a good idea, thanks to the superior quality you receive at much lower prices.

Toll vs. Contract Manufacturing

There is one important distinction to make in terms of services offered by chemical manufacturers. While it often exists under the umbrella of “toll processing,” you must understand what contract manufacturing is in contrast to toll manufacturing.

Toll manufacturing typically deals with “common” chemicals, such as formaldehyde, that have everyday applications. Companies make these common chemicals in large batches and distributed them across a wide market. These chemicals follow a standard formula that manufacturers do not often alter in toll manufacturing.

On the other hand, contract manufacturing is what you need when you want specialty chemicals made. Specialty chemicals are simply specific or altered forms of base chemicals that people don’t use on a widespread scale. Contract manufacturing focuses on creating a specific product that the client needs. But it cannot provide specialty chemicals in large quantities like common chemicals.

One last aspect to consider when choosing between the two is whether or not you, as the client, will be sourcing the materials yourself or leaving it to the manufacturer to handle. With specialty chemicals, client firms will often provide the necessary materials at a certain quality and from a source they trust or desire. However, if a client firm does not or cannot supply the materials, manufacturers will turn to their own vendors to acquire the necessary materials to complete the orders.

Confidentiality Agreements

Because there are many doubts or perceived risks when outsourcing to a third party, custom toll processing within the chemical industry always begins with a Non-Disclosure Agreement. This starts a partnership off on the right foot by giving both parties peace of mind. They can then share information, ideas, and product requirements with each other without worrying that the other party will leak information to competitors or even customers. The confidentiality agreement creates a much easier and secure working relationship that ensures clear and constant communication between the client and manufacturer.

Manufacturing Agreement and Accounting

Once they establish the NDA agreement, the other major agreement between client and manufacturer is a detailed license for the manufacturer to use the customer’s intellectual property, technology, or processes during the manufacturing process should they need them to meet the customer’s specifications. Typically, these agreements are simply detailed blanket purchase orders. However, it’s worth mentioning so that you understand why a manufacturer may be asking for your company’s property and intellectual rights.

To further facilitate communications, the chemical manufacturer will become responsible for sending accounting reports of the different parts of the chemical manufacturing process to their client. Inventory reports exist to coordinate with clients and the deadlines agreed upon. But clients will also receive more detailed reports that show them the results of each batch produced and the physical inventory created as the manufacturer makes these batches.

Other Toll Processing Benefits

We’d like to now go on a small tangent to express some of the other benefits that we have not yet mentioned in the previous topics. These benefits include:

- Logistics: Toll manufacturers will coordinate on-site storage, off-site warehousing, and the delivery of the product to the specified destination.

- Flat fee: Chemical manufacturers only ask for a flat fee, and this acts as another way outsourcing can save you money. This means that no matter the volume of your order, you don’t have to worry about the price going up.

- Reduced labor costs: The main appeal of outsourcing is the specialty equipment chemical manufacturers possess. However, you also don’t have to worry about finding more employees and training them to produce chemicals when the manufacturer already has their own professionals on hand.

- Saved space: Consider how much space you’ll be saving if you don’t have to get the equipment yourself. Attempting to do everything in-house will create a massive cost as you look to provide the space and facilities capable of containing the equipment safely. With toll processing, this is no longer an issue.

Selecting a Manufacturer

To start a partnership with a toll manufacturer, reach out to Capital Resin Corporation. We’d be happy to help you detail a plan and agreement that will meet all of your business’s needs–whether you want common chemicals or specialty chemicals for even the most niche product. When speaking with us, you may either give us a rough overview of your project or sign an NDA right away so that we can be more forthcoming during initial negotiations. You can go for whichever approach is more comfortable for your business.

Some information you’ll need to prepare might include chemical formulas, details surrounding your production schedule, storage capacity, amounts, and any transportation requirements to ensure the delivery goes smoothly. Once we confirm our capabilities can meet your requirements, production can finally begin.