Transporting chemicals can be a bit tricky, especially with how volatile some chemicals can be—either on their own or if they were to mix with others. When the proper considerations are taken, however, the only true danger is the mishandling of the chemicals or carelessness in the precautions. As a resorcinol manufacturer, we’re familiar with the dangers and the best practices for transporting chemicals. Here are the guidelines for the safe transportation of chemicals that you should adhere to.

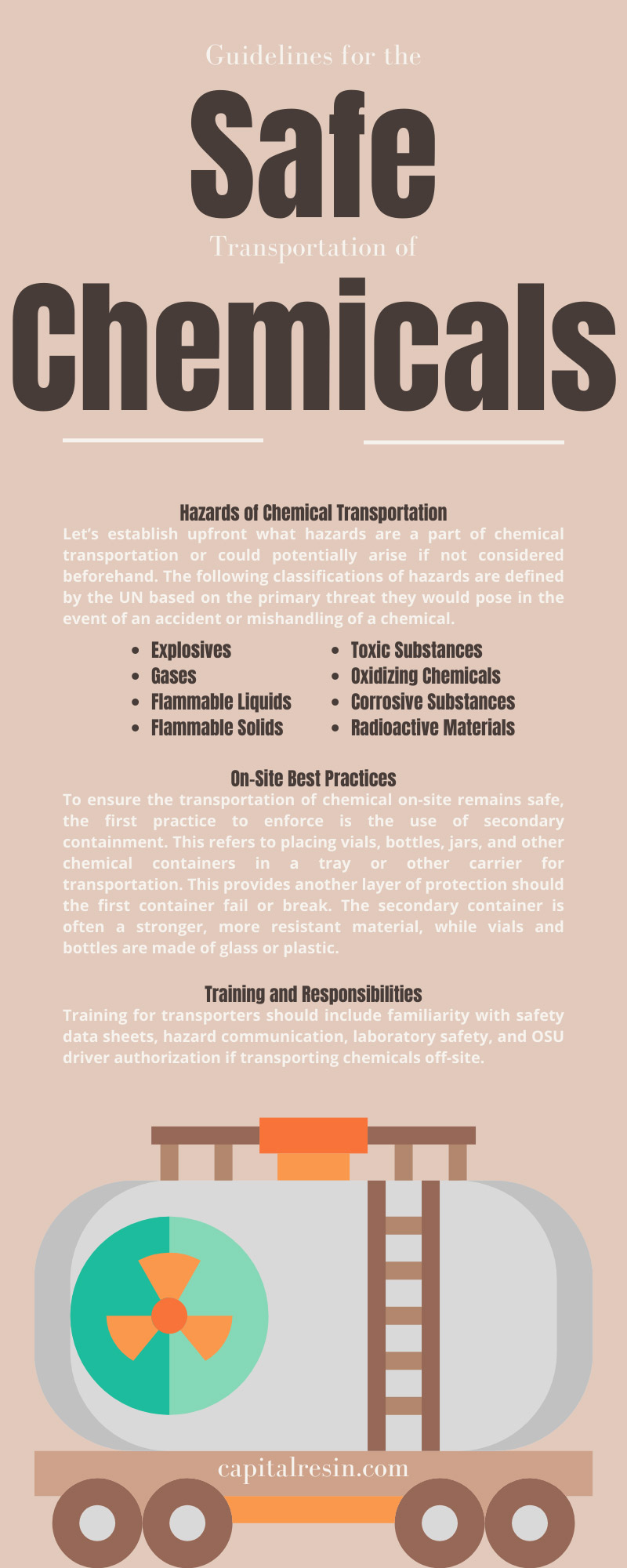

Hazards of Chemical Transportation

Let’s establish upfront what hazards are a part of chemical transportation or could potentially arise if not considered beforehand. The following classifications of hazards are defined by the UN based on the primary threat they would pose in the event of an accident or mishandling of a chemical.

- Explosives – The most volatile chemicals have the potential to explode if handled wrong or mixed with other substances. Examples of explosive chemical products include hairspray, spray paint, and cooking spray. Other chemicals include nitroglycerin for dynamite or azidoazide azide.

- Gases – Some chemicals, like resorcinol, emit gases and fumes that are potentially flammable or naturally toxic and irritable if breathed in. Toxins include fumes that irritate skin and organs as well as the toxins that are plain deadly.

- Flammable Liquids – Chemicals in a liquid state that can easily catch fire, damage buildings, damage the environment, or cause injuries and even fatalities. Alcohol is one of the most common examples of a flammable liquid.

- Flammable Solids – Chemicals that are transported in a solid state are, at times, not only flammable, but also have a risk of spontaneously combusting. Other chemical solids can instead create flammable gas when they come into contact with water.

- Toxic Substances – Categorized into toxic chemicals and infectious chemicals, these don’t just create toxic fumes, but are also toxic if they come into contact with skin or other organic material.

- Oxidizing Chemicals – Chemical material that can speed up the development of fire, intensify a fire, or cause materials to combust spontaneously without an obvious ignition source when exposed to oxygen.

- Corrosive Substances – Chemicals that present a hazard by burning the skin, eyes, and more upon contact. Alternatively, corrosive fumes can irritate and damage the respiratory tract.

- Radioactive Materials – Chemicals and substances that, when spilled, cause enormous and long-lasting damage to the environment, ecosystems, and people.

On-Site Best Practices

Chemical transportation doesn’t necessarily refer to traveling long distances. Most often, chemicals are simply transported to different areas of a facility’s campus. Practices for transporting chemicals on-site can even include simply moving chemicals from room to room. Such short and quick movements of chemicals are common when accidents occur most because safety precautions are often neglected due to moving the substance short distances.

To ensure the transportation of chemical on-site remains safe, the first practice to enforce is the use of secondary containment. This refers to placing vials, bottles, jars, and other chemical containers in a tray or other carrier for transportation. This provides another layer of protection should the first container fail or break. The secondary container is often a stronger, more resistant material, while vials and bottles are made of glass or plastic.

Chemical containers should never be transported by hand. Instead, ensure your facilities have equipment like laboratory carts readily available for chemicals to be transported on. Furthermore, never place incompatible chemicals near each other or within the same container during transportation.

In the case of a spill, ensure spill management kits are readily available so that employees can react quickly and effectively. This assumes, however, that your personnel are trained, as no one unfamiliar with responding to and cleaning chemicals should try to handle a spill, otherwise they place themselves at greater risks of danger.

Anyone transporting chemicals on-site should be equipped with the proper PPE. This prevents the transporter from being harmed in the event of an accident when a chemical comes into contact with their skin.

Off-Site Best Practices

In regard to guidelines for the safe transportation of chemicals off-site, the risks of danger are larger because off-site transportation is typically in greater quantities and spends a lot more time in transit, leaving them vulnerable for longer. To account for these factors, the best practices for off-site transportation are as follow.

Always keep spill kits appropriate for the chemical being transported. Universal spill kits are suitable for spills containing water hydrocarbon materials. Hazmat kits are necessary for chemicals that are corrosive acids, solvents, and other “aggressive” chemicals that are harmful upon contact. Finally, oil-spill kits are specifically for oil spills.

During transit, ensure that all mixed classes of chemicals are properly segregated to prevent hazardous substances from mixing and creating a reaction while being transported. Furthermore, hazardous chemicals need to be thoroughly secured to ensure they move as little as possible during travel. When transporting hazardous substances, the UN requires chemicals to be classified per their designations so that appropriate packaging can be selected for each chemical. The packaging should then be labeled with the appropriate diamond-shaped transport hazard label.

All carriers should be trained and registered to transport hazardous substances for both domestic and international transportation. The transport company should be able to provide you with written evidence of their transporter’s competency and certification beforehand.

Training and Responsibilities

To ensure your employees are properly trained and understand their responsibilities as a transporter of hazardous chemicals, it’s important to reinforce the following knowledge.

Before transporting chemicals, the transporter should be knowledgeable about the substances they are carrying and of the hazards that could potentially arise if the chemicals are not handled properly. In the event of an accident or spill, transporters should know how to clean up the chemicals beforehand and keep emergency contact details on hand to receive the proper aid. Training for transporters should include familiarity with safety data sheets, hazard communication, laboratory safety, and OSU driver authorization if transporting chemicals off-site.

While chemicals can be hazardous, they’re truly only dangerous when the proper safety procedures are not observed. Keeping in mind the guidelines and best practices we’ve outlined here, and your company will be able to minimize the risks.