As a manufacturer, it matters where you get your supplies from. The quality of your raw materials can drastically impact the quality of your finished product. Additionally, the more money you spend on purchasing, storing, and shipping raw materials, the lower your profits will be in the end. Finding a supplier who can give you quality raw materials at a reasonable price is paramount in manufacturing. Check out these five tips for choosing a phenolic resin supplier.

What Is Phenolic Resin?

Before we get to the supplier tips, it’s a good idea to review what phenolic resin is and what makes it special in manufacturing. This information will help you know what to look for when you go shopping for a supplier.

The full name for phenolic resins is phenol formaldehyde resins (PFs), and that extended name should give you an idea of how people make phenol resins. Basically, the resin is a product of a reaction between phenol and formaldehyde, though there are many different variations that yield slightly different products.

Bakelite: The First Synthetic Plastic

As early as the 1860s, scientists discovered how to make plastics. However, they were still using natural ingredients to make them. In 1907, a chemist named Leo Hendrik Baekeland created the first synthetic plastic, which he called Bakelite. While many people have heard of Bakelite, they may not realize that it’s a phenolic resin! That means that phenolic resins are the oldest and most-studied type of synthetic plastic.

What Makes Phenolic Resin Special?

One of the reasons that many people choose to manufacture with phenolic resin is that you can reinforce it with different fibers. Paper, wood, fiberglass, and cotton are a few of the most common reinforcement fibers. To reinforce a phenolic resin, you pour the liquid resin over the base material. During the curing process, the base material becomes laminated.

Common Uses for Phenolic Resin

The ability to reinforce phenolic resin gives manufacturers a huge range of options. People have used phenolic resins to make all kinds of things, including these items:

- Billiard balls

- Countertops

- Coatings

- Adhesives

- Circuit boards

- Fiberglass cloth

- Brake pads

- Duroplast

- Weather- and boil-proof plywood

One of the most common uses for phenolic resin is in lamination for homes and workplaces. If you’ve owned a home with laminate countertops, there’s a good chance that they contained phenolic resin. Resin countertops are also common in labs because of how easy they are to clean.

Phenolic Resin and Art Forgery

One of the most creative uses for phenolic resin has to be forged artwork. During the early 20th century, Dutch painter Han van Meegeren mixed phenolic resin into his paints while making forgeries of famous artists like Vermeer. Once he had baked the finished pieces, the resin helped the paints look aged. He was so good at his forging techniques that art critics remained confused about whether the paintings he had sold were forgeries long after his death.

Choosing a Phenolic Resin Supplier

Now that you know what makes phenolic resins special, you can choose a phenolic resin supplier. Remember that it’s important to compare several different suppliers in your area before deciding who to work with. Below are some tips to streamline the process.

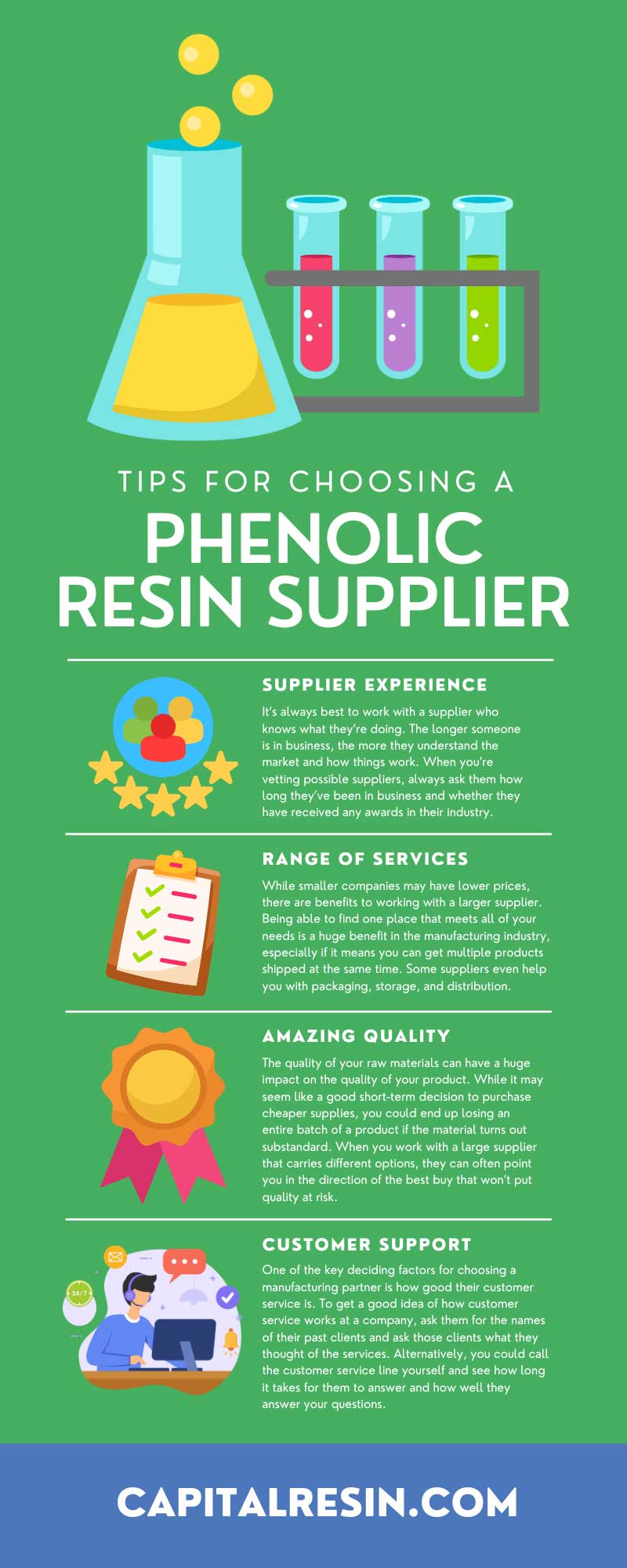

1. Supplier Experience

It’s always best to work with a supplier who knows what they’re doing. The longer someone is in business, the more they understand the market and how things work. When you’re vetting possible suppliers, always ask them how long they’ve been in business and whether they have received any awards in their industry.

2. Range of Services

Some suppliers have a small range of products and services, while others have a huge array of choices. Being able to find one place that meets all of your needs is a huge benefit in the manufacturing industry, especially if it means you can get multiple products shipped at the same time. Some suppliers even help you with packaging, storage, and distribution.

The other thing to consider is whether you’ll need additional services in the future. If you know what kinds of projects are coming up in the future, you can search for a supplier to help with everything. This will save you time choosing a supplier for the next project. In fact, if you tell your supplier that you’re looking for a long-term partnership, they may be able to give you special rates.

3. Amazing Quality

As we said at the beginning of this post, the quality of your raw materials can have a huge impact on the quality of your product. While it may seem like a good short-term decision to purchase cheaper supplies, you could end up losing an entire batch of a product if the material turns out substandard. When you work with a large supplier that carries different options, they can often point you in the direction of the best buy that won’t put quality at risk.

4. Supplier Logistics

One thing you can never ignore in manufacturing is logistics. Currently, global shipping logistics are in chaos, and most systems are overtaxed to the breaking point. Choose partners who know what they’re doing when it comes to shipping raw or partly-finished materials. If the supplier gets it wrong, you could be waiting a long time for the replacement.

5. Customer Support

One of the key deciding factors for choosing a manufacturing partner is how good their customer service is. To get a good idea of how customer service works at a company, ask them for the names of their past clients and ask those clients what they thought of the services. Alternatively, you could call the customer service line yourself and see how long it takes for them to answer and how well they answer your questions.

Finding the Right Chemical Supplier

If you’re looking for a phenolic resin manufacturer, check out Capital Resin. We’ve been in the business for nearly 50 years, so we know the ins and outs of the industry. We’re also able to provide a large range of products and services to help you make your ideas a reality. Capital Resin offers assistance with toll manufacturing, raw materials, temperature-controlled storage, research and development, and more. Contact us today to find out how we can use our vast resources to help you with your next project.