Phenolic paper laminated sheets are revolutionizing the engineering world. These sheets utilize layers of paper and phenolic resin and boast advantages that suit a wide range of industrial applications. Capital Resin Corporation understands these applications and is here to explain all about the benefits of phenolic paper laminated sheets and their uses in various industries.

What Are Phenolic Paper Laminated Sheets?

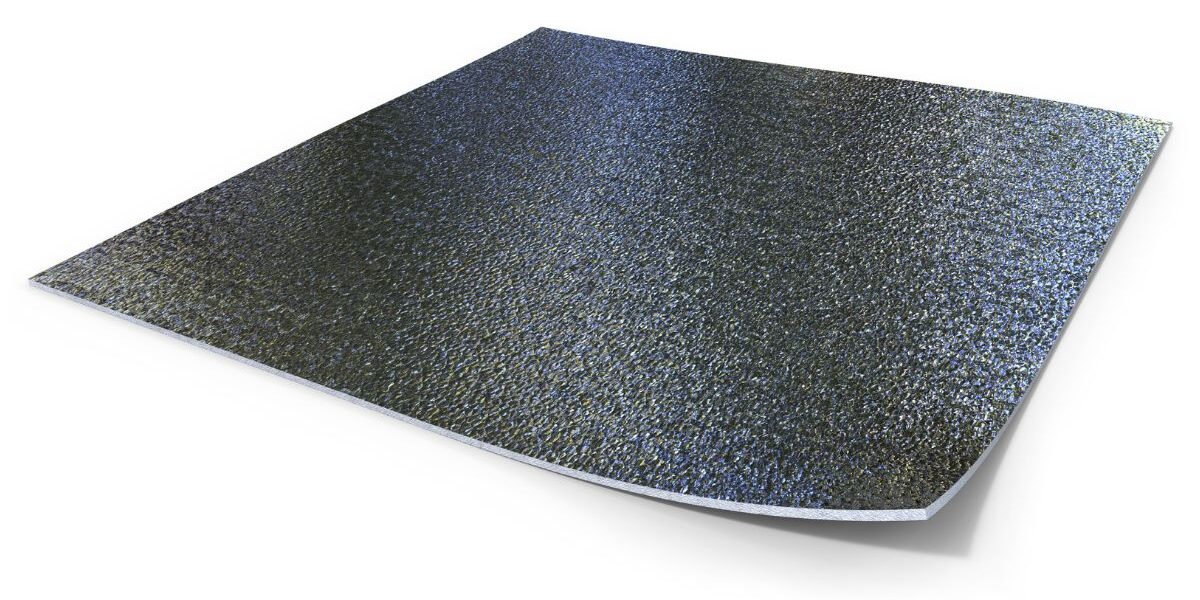

Phenolic paper laminated sheets are composite materials fabricated by layering sheets of paper impregnated with phenolic resin and then chemically bonding them through heat and pressure. This process results in a high-density, durable product that exhibits excellent mechanical strength and resistance to heat, moisture, and chemicals.

Phenolic paper laminated sheets are commonly available in various thicknesses, and industries can utilize them in a wide range of practical applications. Some of the more common examples are insulation, structural components, and even decorative surfaces. Because of their versatility and robustness, phenolic paper laminated sheets are incredibly valuable in industries such as aerospace, automotive, and construction, where reliability and performance are critical.

Durability and Strength

One of the primary benefits of phenolic paper laminated sheets is their exceptional durability and strength. These sheets can withstand significant mechanical stress without deforming or breaking. This makes them ideal for use in environments where high strength is essential, such as in electrical insulation and mechanical components.

Products made with this substance are more robust and last longer than those made with traditional materials that may wear out or corrode over time. Phenolic paper laminated sheets do a much better job maintaining their integrity, which provides reliable performance over extended periods.

Electrical Insulation Properties

Phenolic paper laminated sheets have an industry reputation for their excellent electrical insulation properties. This is particularly important in industries where electrical safety and performance are vital, and where employee safety is at a greater risk. These sheets can effectively prevent electrical currents from passing through, reducing the likelihood of short circuits and electrical fires.

Furthermore, their insulating properties contribute to the efficiency and safety of electrical systems. By using these sheets, engineers can design electrical components and systems that operate more reliably and safely, enhancing overall performance.

Temperature Resistance

In addition to their electrical insulation capabilities, one of the other benefits of phenolic paper laminated sheets is that they exhibit impressive temperature resistance. They can withstand both high and low temperatures without compromising their structural integrity or performance. This makes them suitable for use in environments exposed to extreme temperature variations.

Whether used in high-heat industrial processes or in cold storage systems, phenolic paper laminated sheets remain stable and effective. Their ability to perform well under a wide range of temperatures adds to their versatility and makes them a preferred choice for many engineers.

Chemical Resistance

Phenolic paper laminated sheets are highly resistant to chemicals, including acids, alkalis, and solvents. This resistance is beneficial in industries where exposure to harsh chemicals is common. Materials that can deteriorate when exposed to chemicals can lead to failures and safety hazards.

Using phenolic paper laminated sheets helps mitigate these risks. Their chemical resistance ensures that they remain stable and functional even when in contact with aggressive substances. This property extends their application to environments where other materials might fail.

Moisture Resistance

Another notable advantage of phenolic paper laminated sheets is their aversion and resistance to humidity. These sheets do not absorb water, which prevents them from swelling, warping, or degrading over time. This moisture resistance makes them ideal for use in humid or wet conditions.

In applications where moisture exposure is inevitable, such as in marine environments or outdoor settings, phenolic paper laminated sheets maintain their performance and longevity. Engineers can rely on these materials to deliver consistent results, regardless of environmental conditions.

Versatility in Applications

Versatility is one of their most appealing features. Numerous industries can utilize them in a wide range of applications. From electrical and mechanical engineering to aerospace and automotive sectors, these sheets provide solutions to diverse engineering challenges.

Their unique combination of properties, including strength, insulation, and resistance to various environmental factors, allows different fields to tailor them to their specific needs. Engineers can choose use them in custom applications, ensuring optimal performance and efficiency.

Ease of Fabrication

Phenolic paper laminated sheets are also easy to manufacture, which simplifies the fabrication process. An established phenolic resin manufacturer can manufacture phenolic resins for the companies fabricating the laminated sheets. To suit specific applications, other companies may then cut, drill, or shape these sheets with standard tools, making them easy to work with. This ease of fabrication reduces production time and costs, contributing to overall project efficiency.

Their straightforward workability does not compromise their performance. Despite being easy to fabricate, phenolic paper laminated sheets retain all their beneficial properties, ensuring that the final product meets the required standards and specifications.

Cost Effectiveness

Cost is always a significant consideration in engineering projects. Phenolic paper laminated sheets offer a cost-effective solution without sacrificing quality or performance. Their long life span and minimal maintenance requirements translate to lower overall costs.

By electing to use these sheets, engineers can achieve high-performance results while adhering to budget constraints. The initial investment often pays off through reduced maintenance, longer service life, and improved reliability, making them a financially sound choice.

Environmental Impact

Sustainability is becoming increasingly important in engineering practices. Phenolic paper laminated sheets contribute positively to environmental efforts. Their durability and longevity mean less frequent replacements, reducing waste and resource consumption.

Many manufacturers are now adopting eco-friendly practices in the production of these sheets. This includes using renewable resources and minimizing harmful emissions. Engineers who prioritize sustainability can feel confident in choosing phenolic paper laminated sheets as an environmentally responsible option.

Enhancing Performance in Diverse Industries

The benefits of phenolic paper laminated sheets extend across many industries, enhancing performance and efficiency in every field that utilizes them. In the automotive industry, these sheets contribute to lightweight yet strong components. In aerospace, they provide reliable insulation and structural integrity. In electrical engineering, their insulating properties ensure safety and efficacy.

The adaptability and robust performance of these sheets makes them an indispensable material in modern engineering. By leveraging their strengths, engineers can push the boundaries of innovation and design, achieving superior results across various projects.

As you explore innovative materials for your engineering projects, consider partnering with a trusted phenolic resin manufacturer like Capital Resin Corporation. Our commitment to quality and advanced manufacturing techniques ensures that you receive superior phenolic resin that can meet your specific needs. Contact us today to discuss how our products can enhance your applications and contribute to your project’s success.