Product research and development (R and D) is the backbone of innovation, and it affects materials, design, and end-user experiences. However, R and D comes with complexities that demand a systematic, thoughtful approach. Here are the key dos and don’ts for product research and development to guide you through the process.

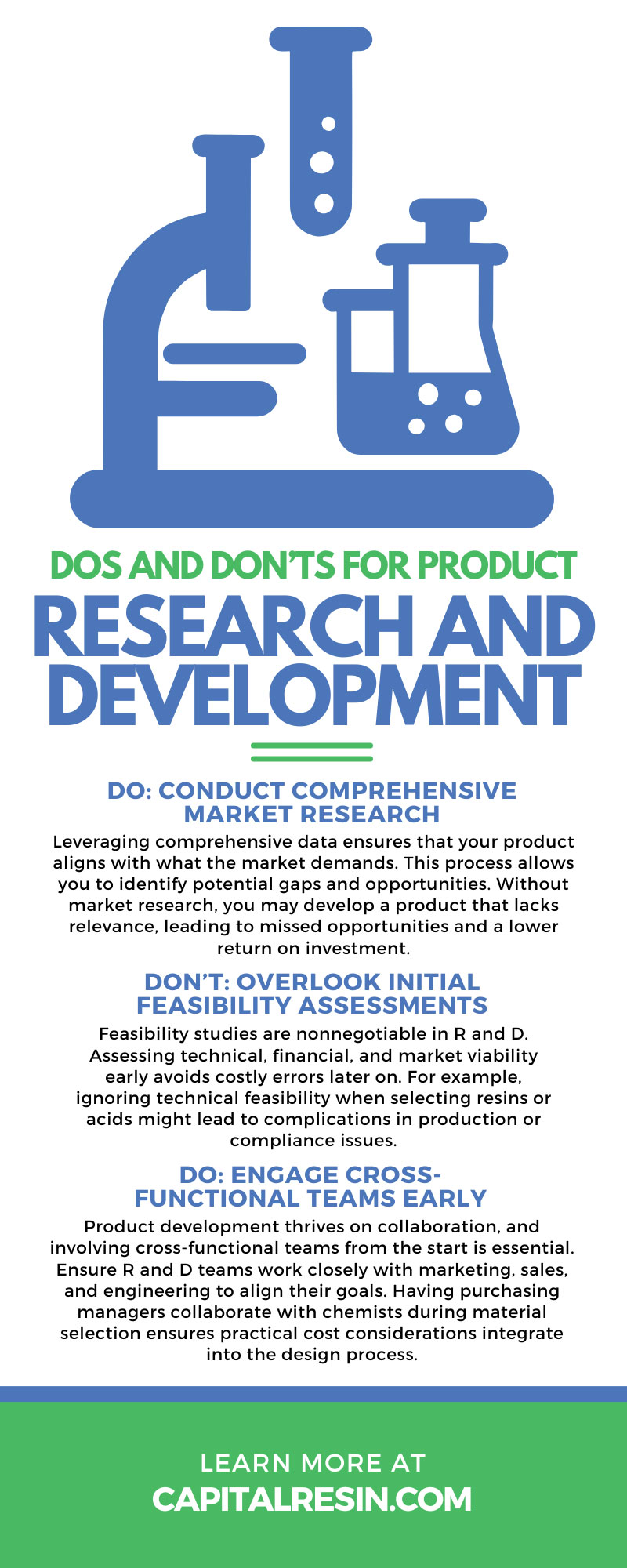

Do: Conduct Comprehensive Market Research

Most products rely on popularity and trends to succeed with customers. Understanding your market is the first step in creating a valuable product. Analyze trends, study customer needs, and evaluate competitor strategies.

Leveraging comprehensive data ensures that your product aligns with what the market demands. This process allows you to identify potential gaps and opportunities. Without market research, you may develop a product that lacks relevance, leading to missed opportunities and a lower return on investment.

Don’t: Overlook Initial Feasibility Assessments

Feasibility studies are nonnegotiable in R and D. Assessing technical, financial, and market viability early avoids costly errors later on. For example, ignoring technical feasibility when selecting resins or acids might lead to complications in production or compliance issues.

Understanding the risks upfront ensures you’re investing resources in a project with a realistic success pathway. Skipping this stage could lead to over-engineered products that lack profitability or customer appeal.

Do: Engage Cross-Functional Teams Early

Collaboration is one of the most valuable tasks on the list of dos and don’ts of product research and development. Product development thrives on collaboration, and involving cross-functional teams from the start is essential. Ensure R and D teams work closely with marketing, sales, and engineering to align their goals. Having purchasing managers collaborate with chemists during material selection ensures practical cost considerations integrate into the design process.

Ensure all teams provide reports of their findings and current processes to keep everyone in the loop and help everyone arrive at the same completion point for the product. This alignment speeds up development and fosters innovations that resonate with end-users and stakeholders alike.

Don’t: Ignore Customer Feedback During Ideation

Customer-centric designs lead to successful products. Engaging directly with customers to understand their pain points and expectations is a considerable benefit to crafting a strategy for success.

Many products fail because they solve problems that don’t exist or overlook critical user demands. Actively seek feedback when conceptualizing products, such as which chemical properties they prioritize to create solutions that provide measurable value. Ignoring this input risks alienating your user base.

Do: Prioritize Quality and Safety Testing

Quality and safety are paramount, particularly when dealing with resins and acids. Comprehensive testing ensures your product performs consistently under real-world conditions while complying with industry standards.

Developing rigorous testing protocols identifies weaknesses in product design early, preventing costly recalls and customer dissatisfaction. If you need to develop a chemical compound that affects food, it requires thorough testing to ensure it is safe. Beyond meeting regulatory obligations, prioritizing safety builds consumer trust, giving your product a critical advantage in competitive markets.

Don’t: Neglect Material Selection and Optimization

Choosing the wrong materials derails even the most innovative product. Resins, acids, and other raw materials must meet the required performance, durability, and environmental standards. Beyond functionality, you must consider compatibility with manufacturing constraints and cost-effectiveness.

Work closely with suppliers and chemists to ensure you’re selecting optimal materials. Neglecting this step often results in expensive redesigns, inefficiencies, or lackluster results.

Do: Allocate Resources for Prototyping and Iteration

Prototyping is one of the most critical phases in product development. It allows you to test your design, gather essential data, and refine your solution before full-scale production. Iterative cycles of prototyping help uncover design flaws or efficiency gaps that might go unnoticed otherwise.

Whether you’re testing chemical compounds or mechanical systems, meaningful prototypes provide invaluable insights. Contract research and development teams can help with prototyping as the professionals hired perform rigorous testing. Dedicate sufficient time and resources here to avoid unanticipated complications during manufacturing.

Don’t: Rush Product Launches Without Validation

Premature product launches often lead to unintended failures. Before going to market, fully validate your product’s performance in different scenarios and ensure it complies with all relevant regulations. Conduct thorough pilot tests to gather user feedback and gauge real-world applicability.

For instance, launching a structural adhesive without durability validation under varied environmental conditions could harm your product’s reputation. Launching without confidence in your product’s readiness is a costly mistake.

Do: Document Each Development Phase Thoroughly

Maintaining detailed records throughout the R and D process is a vital practice for any organization. Proper documentation ensures transparency, facilitates troubleshooting, and supports internal reviews and external audits. From material selection to testing parameters, note every retrievable decision for future reference.

Organized records streamline compliance with regulatory standards and simplify the adoption of lessons learned into future development efforts. Trustworthy documentation protects your business as much as it fuels its success.

Don’t: Underestimate the Importance of Regulatory Standards

Navigating industry regulations is critical, especially when developing products with specialized chemical compositions. Noncompliance with regulations hinders marketability, delays product launches, and invites legal challenges. Research global and regional standards early in development, and involve compliance experts. Proactively managing regulatory requirements solidifies your brand’s reputation for reliability and safety.

Do: Stay Flexible To Adjust Market Strategies

The ability to pivot is a key trait in successful product development. Market dynamics may shift unexpectedly, influencing customer needs and preferences. Develop a framework for regularly monitoring industry trends and market conditions to adapt your approach.

Being proactive about incorporating sustainable materials might offer a competitive edge in an eco-conscious market. Flexibility in strategy allows your product to evolve alongside customer and market demands.

Don’t: Forget To Plan for Sustainable Practices

Sustainability is no longer optional in today’s competitive landscape. Community sentiment and regulatory pressures demand that R and D teams prioritize eco-friendly development practices. Use renewable or biodegradable materials, and consider how manufacturing processes and product lifecycles affect the environment.

After your product hits the market, the work isn’t done. Conduct structured evaluations to measure its success compared to initial targets and collect customer feedback. Analyze metrics for sales performance, customer reviews, and operational efficiency to identify areas for improvement. Use these insights to refine your future R and D projects, enabling stronger market positioning.