Whenever you develop a new product, you have a lot of choices to make. When it comes to the manufacturing process, you have to decide how much you’re willing to invest in new equipment and operations. Add on the costs of hiring process experts, and you could be running up quite the bill.

If the overall cost is starting to sound like more than what your product is worth, you may want to consider toll manufacturing. Read on to discover everything you need to know about toll manufacturing and how it differs from a manufacturing contract.

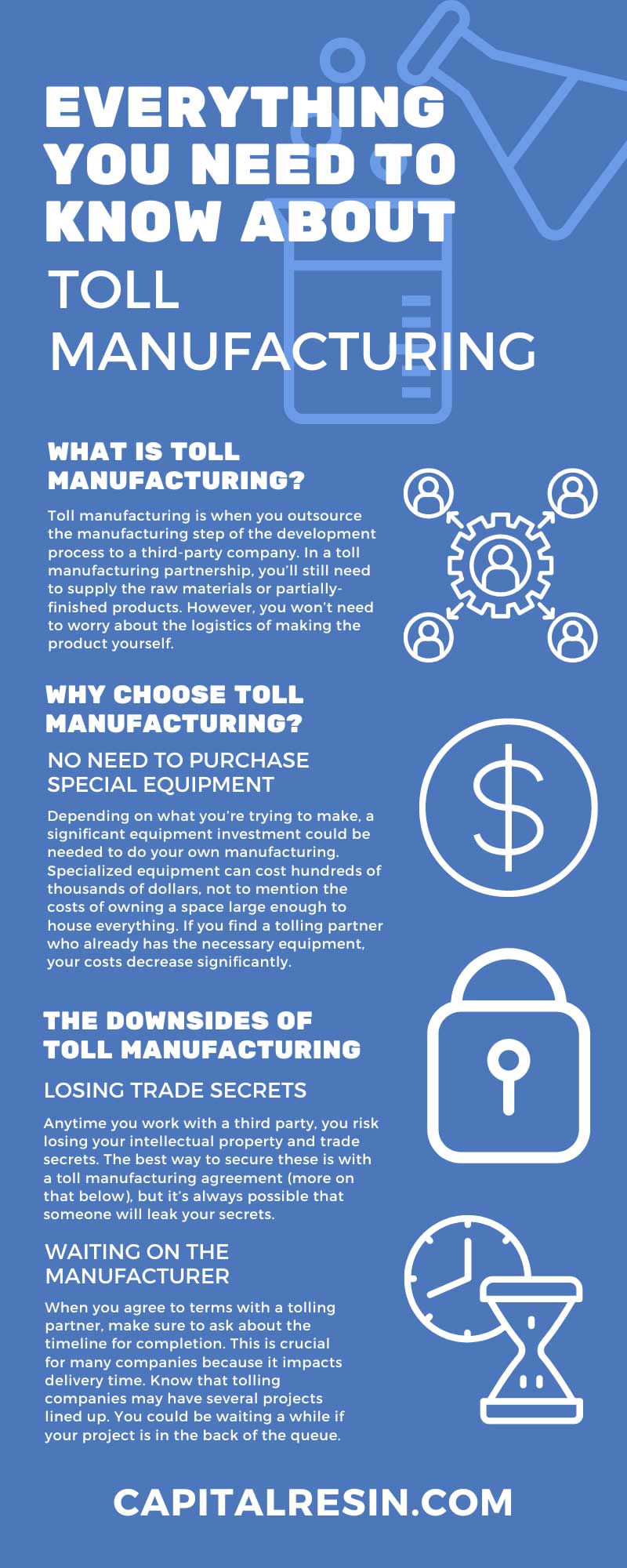

What Is Toll Manufacturing?

Toll manufacturing is when you outsource the manufacturing step of the development process to a third-party company. In a toll manufacturing partnership, you’ll still need to supply the raw materials or partially-finished products. However, you won’t need to worry about the logistics of making the product yourself.

The “toll” in toll manufacturing simply refers to the flat fee that you pay the tolling company. One nice thing about using this system is that the fee won’t increase if your product turns out to be more valuable than predicted.

How Is Toll Manufacturing Different from Contracting?

People often conflate tolling and contracting, but they’re really two separate things. In a contracting partnership, you pay the contractor to do basically everything. They source the raw materials, choose the operations, and make the final product.

Many companies prefer to use toll manufacturing because it helps them retain control over the process. Additionally, the tolling company won’t have access to all your trade secrets, just the part they need to complete their stage of manufacturing.

Why Choose Toll Manufacturing?

There are lots of things to know about toll manufacturing and its benefits. Below, we’ve broken down some of the most important points.

No Need To Purchase Special Equipment

Depending on what you’re trying to make, a significant equipment investment could be needed to do your own manufacturing. Specialized equipment can cost hundreds of thousands of dollars, not to mention the costs of owning a space large enough to house everything. If you find a tolling partner who already has the necessary equipment, your costs decrease significantly.

No Need To Hire Specialized Workers

If you need highly specialized equipment to make a product, chances are you need equally specialized workers to run the manufacturing process. Depending on how niche their skills are, these employees can be quite expensive to hire. When you work with a tolling company, you get to use their experts as part of the toll you pay.

Simplified Process

Beyond the basic logistics of needing the right equipment and the right people to manufacture a product, there are more complicated issues. If you decide to do your own manufacturing, you’ll have to deal with things like capital investments, efficient operation models, and figuring out how to actually manufacture your product. You can skip all of this when you work with a tolling partner.

Easy Warehousing and Shipping

Many companies that specialize in toll manufacturing already know how to store and ship products that are similar to the one you’re developing. They may also have extra space or shipping methods in place. By working with one of these partners, you can take advantage of these additional benefits instead of making arrangements yourself.

The Downsides of Toll Manufacturing

While the benefits of toll manufacturing outweigh the costs for many companies, it’s good to know what to expect. There are a few situations that could negatively impact your business if you don’t account for them.

Losing Trade Secrets

Anytime you work with a third party, you risk losing your intellectual property and trade secrets. The best way to secure these is with a toll manufacturing agreement (more on that below), but it’s always possible that someone will leak your secrets.

Waiting On the Manufacturer

When you agree to terms with a tolling partner, make sure to ask about the timeline for completion. This is crucial for many companies because it impacts delivery time. Know that tolling companies may have several projects lined up. You could be waiting a while if your project is in the back of the queue.

Downsides for the Tolling Partner

If you’re the tolling partner, you should expect that many of your clients will want you to take over the most complicated and expensive steps of manufacturing. This means you’ll be responsible for the quality of more complex products, and your costs could go up.

Tolling Manufacturing Agreements

When you partner with a tolling company, you’ll need to create a tolling manufacturing agreement that spells out the terms of the arrangement. While you should consult a lawyer who specializes in these kinds of documents first, here are a few general things you can expect to find in a tolling manufacturing agreement.

Scope of Work

This section will spell out exactly what the responsibilities of each company are. This way, there’s absolutely no confusion over who supplies the raw materials, who is responsible for shipping, and more.

Quality Control

This section gives you the right to inspect the quality of the manufacturing that the tolling company completes. Depending on how much oversight you want, this section could detail when, how, and how often you’re able to inspect facilities and pre-finished products.

Termination Clause

A termination clause is a section that describes the circumstances under which you (or the tolling company) are allowed to end the agreement prematurely. It also covers what happens when the partnership ends under normal circumstances when everyone has completed their parts of the bargain.

This step is important because it can determine who gets to keep new equipment, paperwork, and digital files related to the project. If you’re worried about trade secrets getting out, this is the section you need to pay attention to.

Non-Compete Clause

In a similar vein, this section protects you from having your tolling partner turn around and sell your trade secrets to your competitors. It boils down to not being able to hurt your business after the partnership ends.

Finding a Chemical Tolling Manufacturer

If you’re looking for an experienced chemical toll processing partner, contact Capital Resin. We offer full tolling services, including warehousing and shipping services. Our area of expertise is working with materials such as phenolic, resorcinol, and amino resins, formaldehyde, polyurethanes, aromatic sulfonic acids, and alkylated phenols. Contact us today to learn about our full range of services.