Particleboard is an incredible material with a wide variety of practical uses. Perhaps it’s so versatile because it’s made with reconstituted wood and strong bonding agents like amino acid resins. But what’s the process behind its creation, and how do amino acids play a role? Discover the answers to those questions and more in our comprehensive guide.

What Is Particleboard?

Just from the title of this article, we can surmise that amino acid resins are used to manufacture particleboard. True as that may be, many of us likely lack a firm understanding of what constitutes particleboard. This is entirely understandable. After all, the material’s namesake isn’t one you hear often. So allow us to explain it in further detail.

In essence, particleboard is a mixture of adhesives and waste-wood products like sawdust or woodchips that, when combined, create a cohesive material. Various adhesives are used in creating particleboard, and the material itself has many dynamic and practical uses.

What Is This Material Used For?

Now that we have a basic knowledge of what particleboard is, we can explore some of the uses for this unique material. The makeup of particleboard makes it perfect for cushioning the structure of sturdier materials. Because of this characteristic, particleboard is often used for:

- Flooring underlayment

- Core materials in doors

- Partitioning and wall paneling

Particleboard can also be used in various types of furniture, such as:

- Kitchen cabinets

- Storage units

- Countertops

Particleboard can also help build things like bookshelves, wardrobes, desks, entertainment centers—the list goes on and on.

As you can see, asking what particleboard is used for is a loaded question. It’s a handy and versatile material that’s excellent in many applications—but so is good old-fashioned, regular wood and a slew of other reconstituted wood products.

This begs the question, what makes particleboard so unique?

What Makes Particleboard Different?

One thing that sets particleboard apart from similar materials is that its composition won’t allow it to warp or bow with exposure to moisture, unlike materials such as plywood. But it can still expand and become unstable when it comes in contact with too much water.

Particleboard is also much denser with more uniformity than regular wood or plywood. Plus, it’s way more cost-effective than many of its counterparts. This makes it an excellent material for projects where budget supersedes the appearance or strength of a material.

Another critical difference between particleboard and other reconstituted wood is simply the materials or particle types used to create them. Particleboard is a term that’s often used to generically describe any product that comprises wood waste and resins or other bonding agents.

However, it’s important to note that particleboard is specific to materials made up of:

- Wood shavings

- Flakes

- Wafer and chips

- Sawdust

- Strands and slivers

On the other hand, materials akin to particleboard exclusively use wood flakes and wafers. In short, particleboard comprises a much more versatile array of materials than many of its counterparts.

Where Do Amino Acid Resins Come In?

Indeed by now, we know what particleboard is, some of its various applications, and what sets it apart from other materials like it. Thus, we’ve finally come to the moment of truth—the role amino acid resins play in creating particleboard. As briefly mentioned, particleboard comprises wood-waste products and any variety of adhesives or bonding agents.

The binder used in particular particleboard is up to the manufacturers in charge of creating it. We can infer then that amino acid resins are another bonding agent used to make particleboard for all the wonderful applications we’ve just learned about.

What’s the Process of Making Particleboard With Amino Acids?

But what’s the actual process behind manufacturing this material? We’re glad you asked. The basics of the process aren’t complicated. Manufacturers acquire the proper materials; they create a very carefully curated mixture of wood waste and the amino acid resins of their choosing.

From there, the mixture is transformed into solid sheets, and the incredible material we know as particleboard is conceived. With that said, this is just a general overview of the creation of particleboard. The actual manufacturing of particleboard is much more detailed. That’s why we’ve taken some time to break down the specifics of the process below.

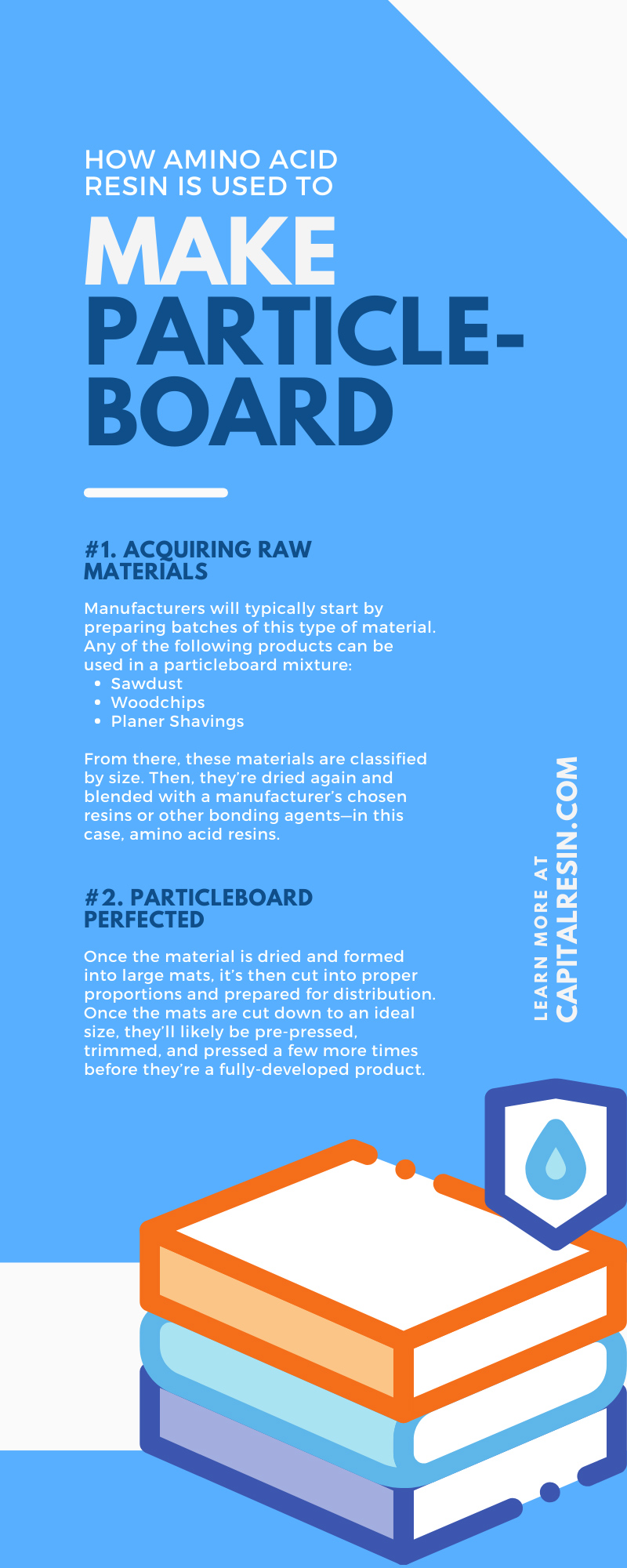

#1. Acquiring Raw Materials

Of course, the first step in creating particleboard with amino acids is acquiring all the raw materials required to do so. We’ve discussed that particleboard is primarily made up of wood-waste products.

So manufacturers will typically start by preparing batches of this type of material. Any of the following products can be used in a particleboard mixture:

- Sawdust

- Woodchips

- Planer Shavings

From there, these materials are classified by size. Then, they’re dried again and blended with a manufacturer’s chosen resins or other bonding agents—in this case, amino acid resins.

Sometimes wax will also be added to the mixture. This process forms the compound that will later be shaped into mats, heat-pressed, and finished into particleboard.

#2. Particleboard Perfected

Once the material is dried and formed into large mats, it’s then cut into proper proportions and prepared for distribution. Once the mats are cut down to an ideal size, they’ll likely be pre-pressed, trimmed, and pressed a few more times before they’re a fully-developed product.

The presses apply the necessary pressure to activate the amino acid resins and ensure optimal bonding. After pressing, the resulting boards are left to cool. From there, they’re stacked, sanded, and trimmed to their final dimensions. Then, any other finishing tasks are performed on the particleboard, and soon after, they’re ready to go.

Much more attention to detail and precise mathematics go into this process. But this is basically how particleboard is made using amino acid resins and any other types of resin or bonding agents that manufacturers might utilize.

Final Takeaways

Hopefully, this guide clearly explained the basics of how particleboard is made with amino acid resins. Moreover, we hope you learned about the value of waste-wood products’ versatility, cost-effectiveness, and eco-friendliness. And remember—if your facility is ever looking for amino acid or urea formaldehyde resin manufacturers to help you create excellent particleboard, Capital Resin Co is just a phone call away.