Innovation is a powerful tool for advancing human knowledge. In the world of chemistry, innovation helps chemists create the building blocks for new products that improve our quality of life. It also aids them in creating environmentally friendly chemicals and production methods that help the planet. Discover how chemical manufacturers help protect the environment.

Understanding Green Chemistry

Green chemistry is the term given to efforts that reduce and reverse the negative impacts of chemical manufacturing on the environment. These efforts include things like biodegradable chemicals that safely return to the earth through natural cycles. Research centers and mass manufacturing facilities can take advantage of green chemistry’s best practices, which are explained below.

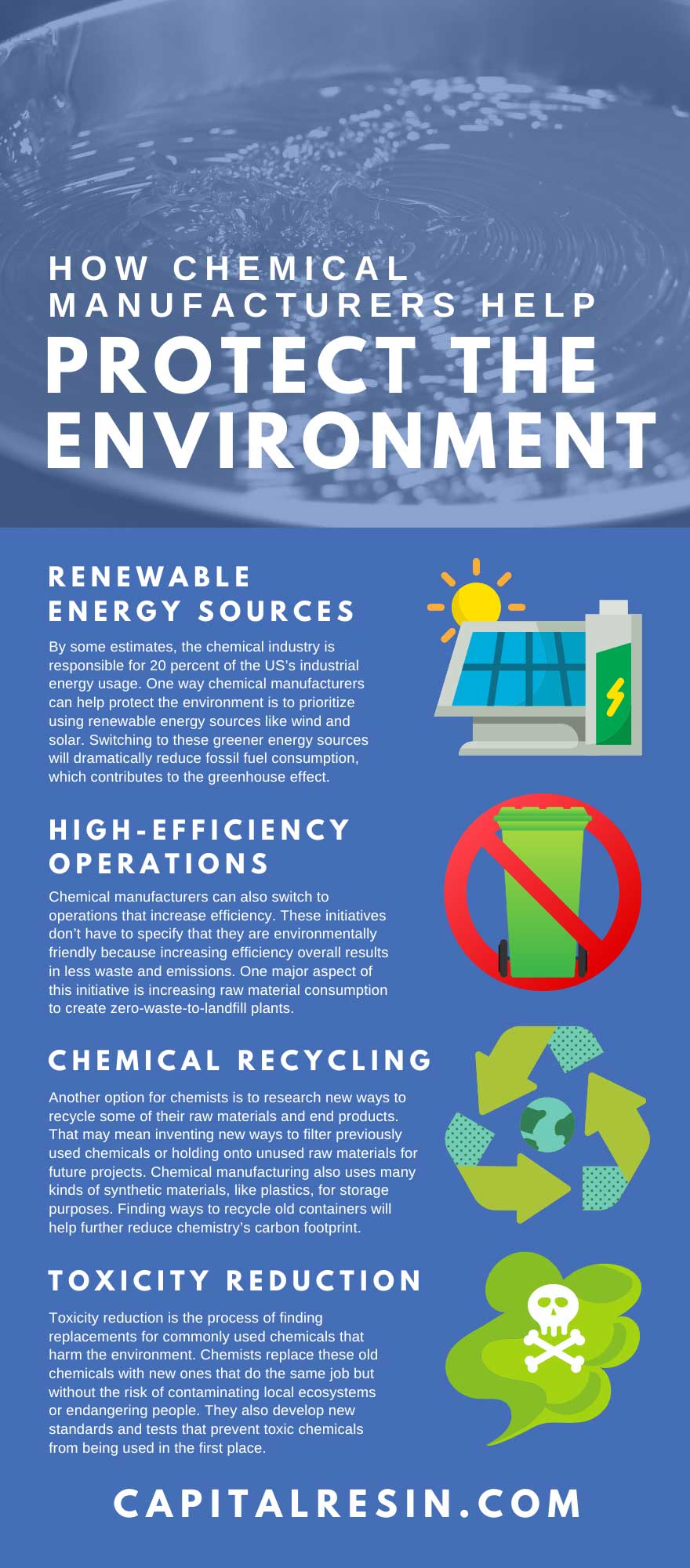

Renewable Energy Sources

Chemical manufacturing plants use an incredible amount of electrical power. By some estimates, the chemical industry is responsible for 20 percent of the US’s industrial energy usage. One way chemical manufacturers can help protect the environment is to prioritize using renewable energy sources like wind and solar. Switching to these greener energy sources will dramatically reduce fossil fuel consumption, which contributes to the greenhouse effect.

Renewable Fuel Chemistry

Chemists play a vital role in developing green fuels that can one day replace fossil fuels. The goal of this research is to develop fuels from sources that can’t be used up, like biofuels from crops. To count as a green fuel, these biofuels also need to have a neutral or positive impact on local food supply chains. They must also avoid harming local ecosystems. Some examples of biofuels include:

- Ethanol—corn and sugarcane

- Biodiesel—plant oil and animal fat

- Green diesel—algae and other plants

- Biogas—methane from animal waste

High-Efficiency Operations

Chemical manufacturers can also switch to operations that increase efficiency. These initiatives do not have to specify that they are environmentally friendly because increasing efficiency overall results in less waste and emissions. One major aspect of this initiative is increasing raw material consumption to create zero-waste-to-landfill plants.

Energy Recycling

One example of how chemical manufacturers can be more eco-friendly is Capital Resin’s energy recycling program. We know that some chemical processes generate a lot of heat, so we found a way to recycle that heat into steam. The steam from our recycling program fuels other processes all over our facility. It is a win-win for us and the environment!

Chemical Recycling

Another option for chemists is to research new ways to recycle some of their raw materials and end products. That may mean inventing new ways to filter previously used chemicals or holding onto unused raw materials for future projects. Chemical manufacturing also uses many kinds of synthetic materials, like plastics, for storage purposes. Finding ways to recycle old containers will help further reduce chemistry’s carbon footprint.

The Plastics Revolution

One of the most important areas of research in chemical recycling is plastics. That is because the world generates a lot of it, and most plastics are not very biodegradable. With more advanced chemical processes, scientists can break down used plastic and reform it into high-quality recycled plastics that are almost indistinguishable from the original plastic. Recycled plastics reduce the need to create new plastic, resulting in less waste and fewer emissions from plastic production.

Toxicity Reduction

Toxicity reduction is the process of finding replacements for commonly used chemicals that harm the environment. Chemists replace these old chemicals with new ones that do the same job but without the risk of contaminating local ecosystems or endangering people. They also develop new standards and tests that prevent toxic chemicals from being used in the first place.

Lower Toxicity Reduces Danger

By utilizing fewer toxic ingredients, chemical plants can avoid messy—and expensive—cleanups that result from equipment malfunctions and spills. Then, workers will not need higher levels of personal protective equipment (PPE), which are expensive and typically single use. Additionally, plants and labs can choose cleaning solutions with low toxicity to prevent water pollution.

Greener Downstream Products

When chemists find new ways to replace toxic ingredients with new, eco-friendly ones, it has a long-lasting impact on the environment. That is because these chemicals go into all kinds of downstream products, whether they are industrial cleaners or makeup products. Green chemicals can have a positive impact on many industries, including:

- Food and beverages

- Paper products

- Agriculture and home gardening

- Packaging and shipping

- Aerospace

- Electronics

- Defense

Practical Steps To Take Now

If you are in charge of a chemical manufacturing or research facility, there are several things you can do today to start practicing green chemistry. These steps can help put you on the path toward decreasing your environmental impact:

- Switch to LED light bulbs

- Begin a recycling program

- Change out toxic cleaning solutions for less toxic ones

- Install solar panels

- Apply for the SOCMA ChemStewards program

LEDs and Solar Power

By switching out your old incandescent bulbs to LED, you’ll get brighter, better lighting at a significantly lower energy cost. LED lights shed light in multiple directions, and they use less energy than incandescent bulbs. Installing solar panels can reduce your costs further since you will provide your own power.

Recycling Program

While learning how to recycle raw materials and end products may take more time, a basic recycling program is easy to set up. This kind of program deals with employee waste, like cans, bottles, paper, etc., rather than chemical waste. Talk to your local recycling center about setting up a program at your business.

Industrial Cleaners

Check the bottles of your favorite industrial cleaners to see if they mention any green initiatives. If not, you can switch to cleaners featuring non-toxic ingredients that biodegrade easily. Many companies sell green industrial cleaners in bulk online.

SOCMA ChemStewards

Capital Resin is proud to be certified by the Society of Chemical Manufacturers and Affiliates ChemStewards program. This intensive program requires three years of careful analysis and implementation of green chemistry best practices, including an on-site audit. Following certification, companies must submit annual performance metrics to retain their certifications. You can begin the process today by applying to the SOCMA ChemStewards program.

Environmentally Responsible Chemical Manufacturers

If you are looking for a custom chemical manufacturer who follows green chemistry best practices, contact Capital Resin. We have experience creating high-quality products for agriculture, automotive coating, electronics, personal care products, and more. We also offer storage, packaging, and shipping solutions for your final products. Contact us today to find out how we can help fulfill your manufacturing needs.