A powerful catalyst agent in a variety of industries such as pharmaceuticals, pesticides, or polymerization stabilization, p-Toluenesulfonic acid has become so common and widespread it can be easy to forget the material safety for p-Toluenesulfonic acid. To ensure you take the proper steps and precautions, let’s review the material safety data toluene sulfonic acid manufacturers use to gain a better understanding of this agent.

Potential Health Risks

The most important thing to establish upfront is that p-Toluenesulfonic acid will cause burns if it comes into contact with human skin or eyes, causing potentially permanent damage. It can also irritate the respiratory system upon ingestion or inhalation. If inhaled or ingested, pTSA will cause chemical burns to the respiratory tract or gastrointestinal tract. These effects may not be fatal—but they certainly are painful, and should be addressed immediately and decisively.

First Aid Measures

If an employee is exposed to the acid, then the material safety for p-Toluenesulfonic acid dictates a few different procedures depending on the exposure.

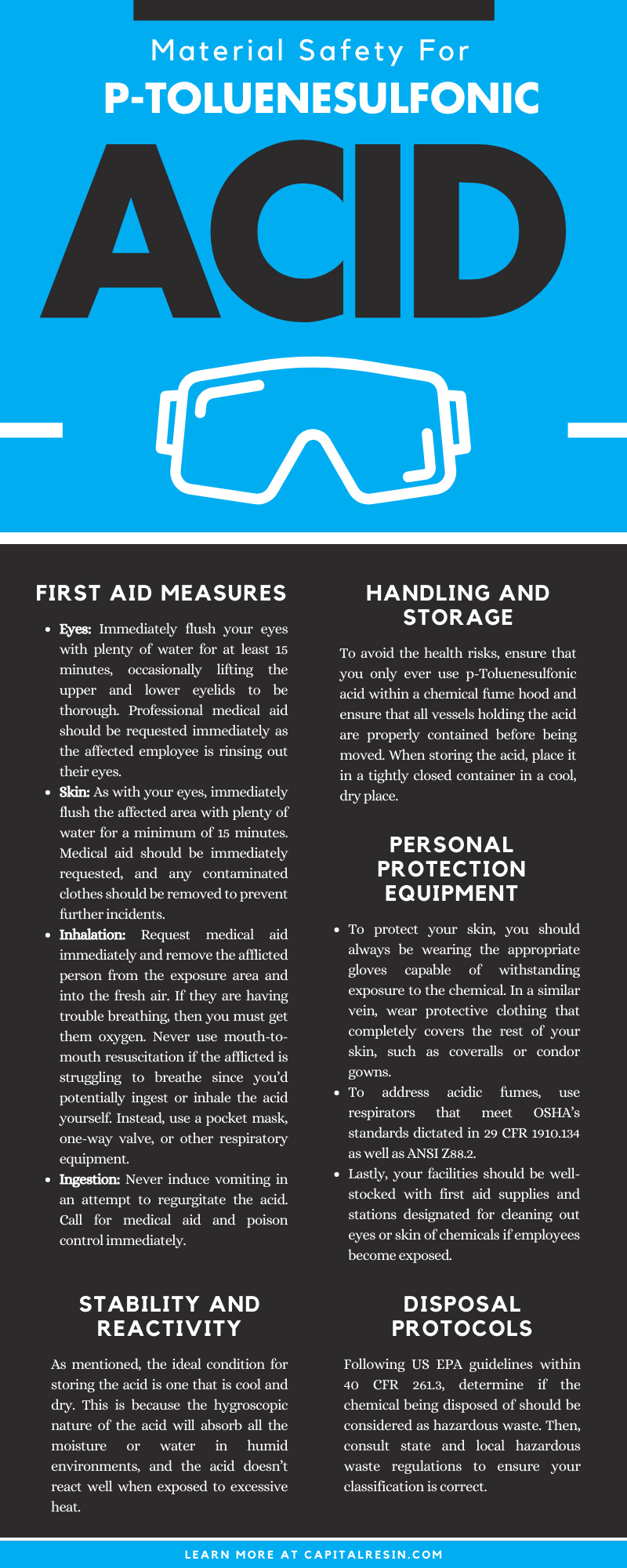

- Eyes—Immediately flush your eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids to be thorough. Professional medical aid should be requested immediately as the affected employee is rinsing out their eyes.

- Skin—As with your eyes, immediately flush the affected area with plenty of water for a minimum of 15 minutes. Medical aid should be immediately requested, and any contaminated clothes should be removed to prevent further incidents.

- Inhalation—Request medical aid immediately and remove the afflicted person from the exposure area and into the fresh air. If they are having trouble breathing, then you must get them oxygen. Never use mouth-to-mouth resuscitation if the afflicted is struggling to breathe since you’d potentially ingest or inhale the acid yourself. Instead, use a pocket mask, one-way valve, or other respiratory equipment.

- Ingestion—Never induce vomiting in an attempt to regurgitate the acid. Call for medical aid and poison control immediately.

Handling and Storage

To avoid the health risks, ensure that you only ever use pTSA within a chemical fume hood and ensure that all vessels holding the acid are properly contained before being moved. When storing the acid, place it in a tightly closed container in a cool, dry place. Minimize the accumulation of dust to prevent contamination.

Accidental Release Measures

If there is ever an accidental release of the acid—such as spills or leaky containers—then the best first step is to have everyone within the area equip their personal protection equipment. After everyone is protected, you can then address the issue. When addressing spills and leaks, vacuum or sweep up the material, which should then be contained within a proper disposal container. As you go about cleaning up the spill or leak, avoid generating dust and provide ventilation to rid the room of fumes. Be careful not to release the chemical into the environment.

Fire-Fighting Measures

If a fire is ever involved, begin with acquiring full personal protection equipment and a self-contained breathing apparatus. Then, when addressing the chemical fire, you have a few options for extinguishing it: water spray, dry chemical, carbon dioxide, and chemical foam. P-Toluenesulfonic acid, in particular, does not react well with fire or excessive heat—but it does demand a lot of oxygen, hence why using carbon dioxide to starve the fire is one of the recommended methods.

Personal Protection Equipment

As we’ve mentioned a few times now, any sort of emergency requires that you equip the proper personal protection equipment immediately. To be more specific, the equipment you should have on hand to protect yourself and your peers include protective eyeglasses or chemical safety goggles that meet OSHA’s standards as stated in regulation 29 CFR 1910.133.

To protect your skin, you should always be wearing the appropriate gloves capable of withstanding exposure to the chemical. In a similar vein, wear protective clothing that completely covers the rest of your skin, such as coveralls or condor gowns.

To address acidic fumes, respirators that meet OSHA’s standards dictated in 29 CFR 1910.134 as well as ANSI Z88.2. Such regulations will help guide you in your selection of respirators so that you can be confident that your choice of equipment is effective and durable.

Lastly, your facilities should be well-stocked with first aid supplies and stations designated for cleaning out eyes or skin of chemicals if employees become exposed. Taking precautionary measures to stock your facilities is necessary and will reduce risks of liability if you can quickly address the situation and solve it before any serious harm or damage is done.

Physical and Chemical Properties

Now that we’ve covered emergency protocols, we can take a closer look at the properties of p-Toluenesulfonic acid. In its physical state, the acid appears as pink or white crystals with very little in the ways of an aroma. In regard to its chemical properties, the freezing and boiling point of pTSA is between 103-106 degrees Celsius and is soluble. One of the more notable aspects of the acid is that it’s hygroscopic, meaning it absorbs moisture out of the air.

The molecular formula of pTSA is C7H8O3S.H2O and has a molecular weight of 190.22.

Stability and Reactivity

As mentioned, the ideal condition for storing the acid is one that is cool and dry. This is because the hygroscopic nature of the acid will absorb all the moisture or water in humid environments, and the acid doesn’t react well when exposed to excessive heat.

Materials that are incompatible with the acid include metals, strong oxidizing agents, and strong bases. Products that will cause decomposition of the acid are carbon monoxide, oxides of sulfur, and carbon dioxide. One silver lining, however, is that you won’t have to worry about polymerization.

Disposal Protocols

When there’s been a spill or leak that needs to cleaned up, you’ll need to make a few considerations in order to properly dispose of it. Following US EPA guidelines within 40 CFR 261.3, determine if the chemical being disposed of should be considered as hazardous waste. Then, consult state and local hazardous waste regulations to ensure your classification is correct. Take any extra considerations or steps necessitated by local authorities.