Chemical manufacturing requires extensive experimentation and manipulation of chemicals to achieve specific outcomes. So, it’s only natural that chemical manufacturers invest a large amount of time and resources into their research and development departments.

This investment, in turn, benefits other businesses as this not only gives them a wider range of options when it comes to custom chemical manufacturing, but they can also rent out the services of a chemical manufacturer’s research and development department for their own needs.

This collaboration allows companies without in-house R&D capabilities to innovate and solve complex challenges. By leveraging external expertise, businesses can develop novel products and improve existing processes without the massive upfront cost of building their own labs. Take a closer look at research and development in chemical manufacturing to get a better idea of how it contributes to industry excellence.

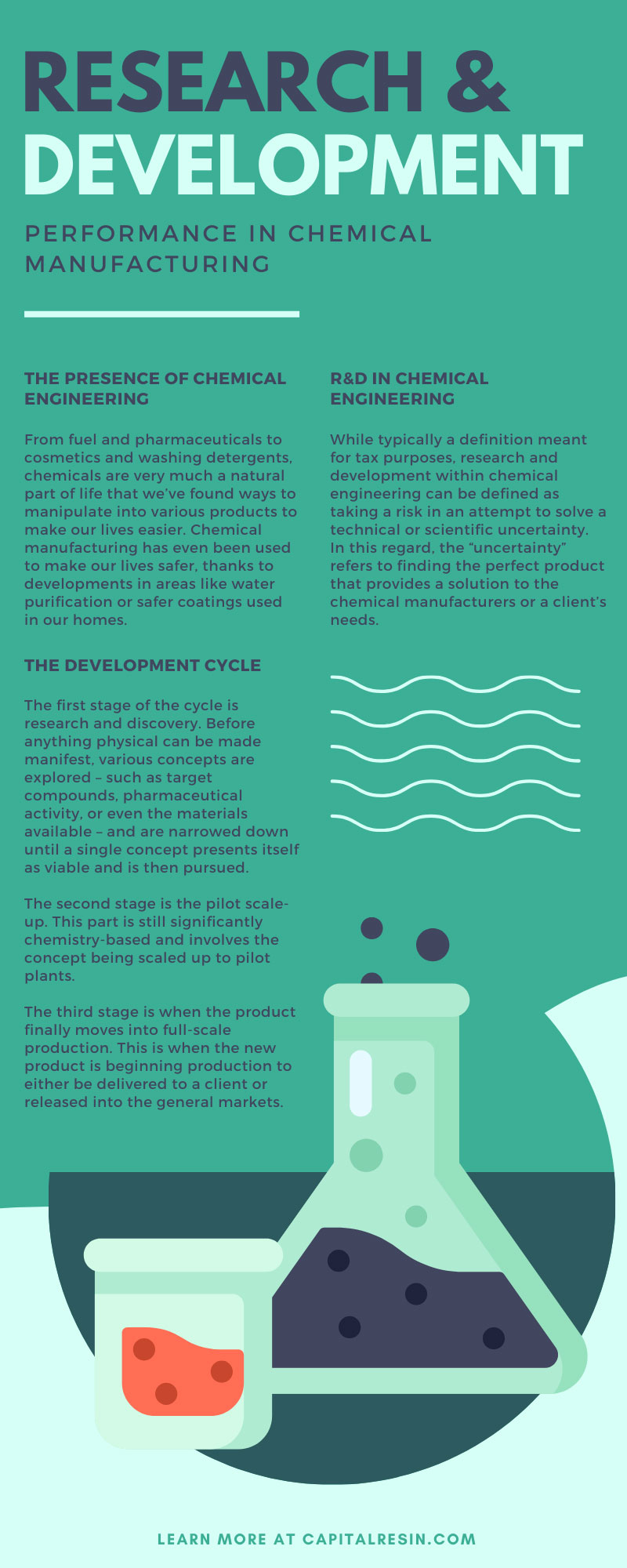

The Presence of Chemical Engineering

While chemical manufacturing may seem like a very industrial concept that doesn’t affect the common person’s daily life, it’s much further reaching than you’d think. Manufacturers can manipulate chemicals into various products that make life easier, from fuel and pharmaceuticals to cosmetics and washing detergents. Chemical manufacturing even helps make environments safer, thanks to developments in areas like water purification or safer coatings used in homes.

The largest source of fear for chemical manufacturing stems from those who simply don’t understand it or receive misinformation. For this reason, we want to highlight how the research and development performance in chemical manufacturing impacts industries large and small. Chemical manufacturers actively work to develop new and improved products that promote a safer lifestyle for all.

R&D in Chemical Engineering

While typically a definition meant for tax purposes, research and development within chemical engineering can refer to taking a risk in an attempt to solve a technical or scientific uncertainty. In this regard, the “uncertainty” refers to finding the perfect product that provides a solution to the chemical manufacturers or a client’s needs.

Some chemical formulas have become an industry standard and are far less of a risk to produce. However, when it comes to developing specialty chemicals, the risk increases because of the greater amount of time and resources required to undergo experimentation to find the perfect formula. Leading chemical production companies build their business models around navigating this uncertainty efficiently.

Some good examples of research and development within the chemical industry include:

- Advancement within the chemical sector by experimenting with chemical structures.

- Developing new or improving upon existing materials used in manufacturing.

- Finding new ways to make processes more efficient or effective.

- Solving technical problems within the chemical production process.

- Developing new polymers for specific, niche projects.

- Working with bulk chemicals like gas and oil to make it safer, more efficient, and less impactful on the environment.

Some examples of the work chemical manufacturers do for other industries include:

- Developing new and improving upon existing pharmaceuticals.

- Developing safe pesticides for crops.

- Improving materials to be recyclable.

- Creating perfumes that last longer, reduce sensitivity, and contain new fragrances.

The Development Cycle

Now that you know how widespread chemical manufacturing reaches and how it impacts daily living, take a closer look at the development cycle of chemical research.

The structured approach chemical production companies follow ensures new products move from concept to market efficiently and safely. Expert chemical manufacturers refine this process continuously to innovate faster and maintain a competitive edge, turning initial ideas into valuable commercial products. This disciplined methodology separates successful ventures from failed experiments, ensuring the effective allocation of resources at every stage of the journey from the laboratory bench to the commercial marketplace.

Research and Discovery

The first stage of the cycle is research and discovery. Before anything physical happens, research teams explore various concepts, such as target compounds, pharmaceutical activity, or even the materials available. They narrow these ideas down until a single concept presents itself as viable, which they then pursue.

This ideation phase sets the foundation for all subsequent work. A flawed or poorly researched concept can lead to wasted time and significant financial loss down the line. That’s why top-tier chemical production companies employ teams of scientists to vet ideas rigorously against market needs, scientific feasibility, and potential return on investment.

Pilot Scale-Up

The second stage is the pilot scale-up. This significantly chemistry-based part involves scaling the concept up to pilot plants. Pilot plants are pre-commercial production systems that either test out newer systems, observe changes in processes, or in the case of developing a new product, produce small volumes of conceptual product for more testing and observation.

Beyond developing a test product, it allows a physical demonstration of the process required to create the final product. This allows chemists to optimize or fix any issues that arise in the production process.

This phase is crucial for identifying unforeseen challenges related to scaling. What works in a small glass beaker may not work the same way in a 500-gallon reactor. Factors like heat transfer, mixing efficiency, and reaction kinetics can change dramatically, requiring process engineers to develop new strategies for control and optimization before committing to a full-scale build.

Full-Scale Production

The third stage is when the product finally moves into full-scale production. Production begins on the new product either to deliver it to a client or release it into the general markets.

At this stage, new issues can still arise, such as differing heating and cooling rates due to the much larger production scale. Supply chain logistics, quality control at high volumes, and long-term process stability become the primary focus.

Types of Chemical Engineering

The development process isn’t a one-size-fits-all scenario, as there are a few different types of chemical engineering that need consideration. Each category presents unique challenges and opportunities for innovation. Understanding these distinctions helps clarify how chemical manufacturers conceptualize different chemical products and bring them to market.

Specialty Chemicals

Specialty chemicals are those that interact and affect the things they encounter, also giving them the name “effect,” “performance,” or “formulation” chemicals. Some good examples of these specialty chemicals include adhesives, lubricants, cleaning products, and cosmetic additives. Their value lies not in their chemical composition alone, but in what they can do.

Fine Chemicals

Fine chemicals are high quality and produced in small quantities. These are typically the custom chemicals clients will go to chemical manufacturers for, to have a solution researched and developed to solve their problem. These are often more expensive because they need production in such specific quantities and require development, as opposed to the common chemicals that have a standardized formula.

Polymers

Polymers are molecules joined together in long chains. While natural examples of polymers include silk and even human DNA, there are also man-made polymers.

Examples include PVC, siloxane, and plastics. In fact, plastics account for about a third of the chemical industry’s dollar value alone.

Composites

Composites are compounds made up of two or more materials. These composites are either “matrixes” or “reinforcement,” to significantly alter or create new properties that work together to be greater than the sum of their parts. For example, steel is a common alloy that uses materials like chromium to enhance its resistance to oxidation, which prevents rust.

Chemical manufacturers excel in R&D, innovating products and processes that enhance industries like agriculture, pharmaceuticals, and sustainable manufacturing.