Amino resins are highly versatile polymers known for their durability, resistance, and adaptability. Various industries use these resins for a range of applications, from automotive and construction to textiles and coatings. We explore the many facets of amino resins, their applications, and the benefits they offer to businesses in the post below. Understanding the versatility of amino resins can help purchasing managers, chemists, and business owners make informed decisions when selecting materials for their projects.

What Are Amino Resins?

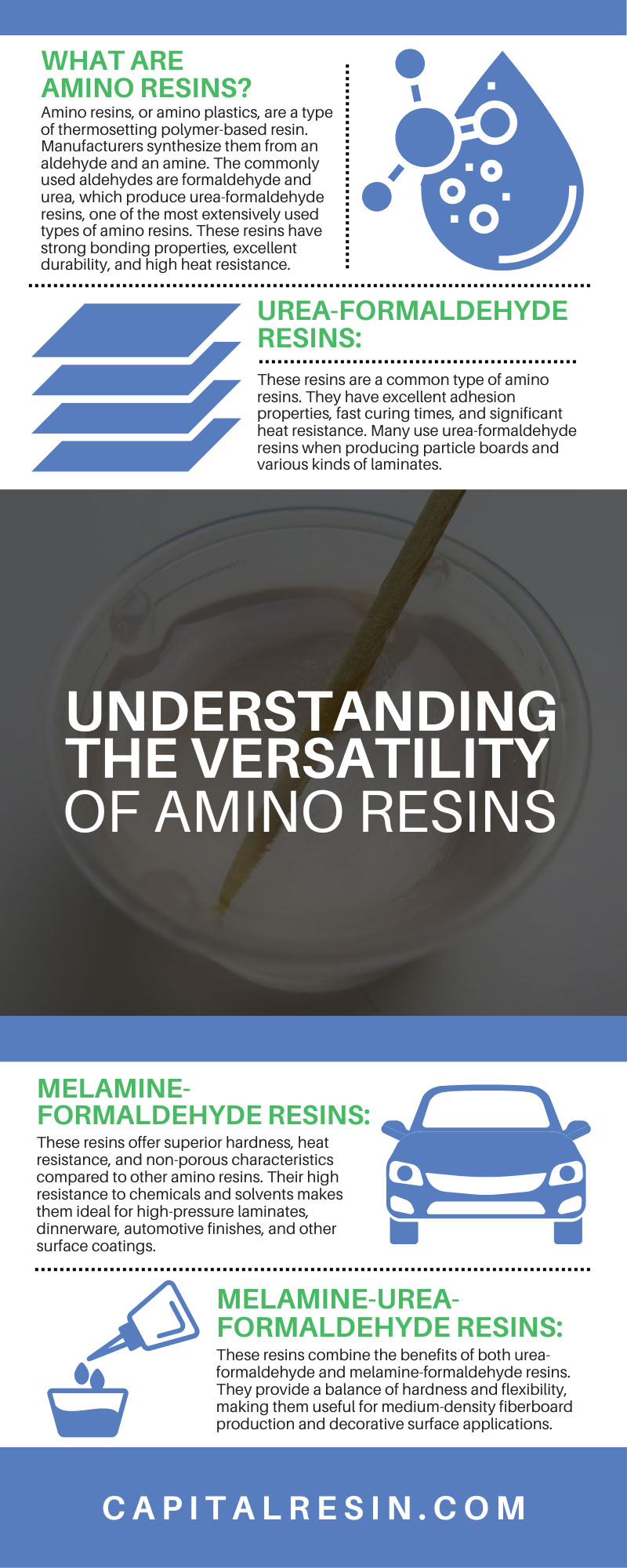

Amino resins, or amino plastics, are a type of thermosetting polymer-based resin. Manufacturers synthesize them from an aldehyde and an amine. The commonly used aldehydes are formaldehyde and urea, which produce urea-formaldehyde resins, one of the most extensively used types of amino resins. These resins have strong bonding properties, excellent durability, and high heat resistance. Amino resins undergo a chemical reaction under heat and pressure, which leads to their “thermosetting” property. This irreversible process makes these resins highly sturdy and resistant to deformation under heat, making them an ideal choice for a wide range of industrial applications.

Different Types of Amino Resins

Amino resins come in several types, each having unique properties that make them suitable for specific applications. Some of the most common types include:

Urea-Formaldehyde Resins: As previously mentioned, these resins are a common type of amino resins. They have excellent adhesion properties, fast curing times, and significant heat resistance. Many use urea-formaldehyde resins when producing particle boards and various kinds of laminates.

Melamine-Formaldehyde Resins: These resins offer superior hardness, heat resistance, and non-porous characteristics compared to other amino resins. Their high resistance to chemicals and solvents makes them ideal for high-pressure laminates, dinnerware, automotive finishes, and other surface coatings.

Melamine-Urea-Formaldehyde Resins: These resins combine the benefits of both urea-formaldehyde and melamine-formaldehyde resins. They provide a balance of hardness and flexibility, making them useful for medium-density fiberboard production and decorative surface applications.

Businesses can better identify the most suitable type for their specific needs and applications by understanding the different types of amino resins. Companies can work with chemical engineers and producers to help find the compound that best suits their end goals.

Key Applications of Amino Resins

Amino resins, due to their diverse properties, find numerous applications across various industries. Below are some key uses of these versatile polymers:

Particle Boards and Laminates: As referenced above, many use urea-formaldehyde resins when manufacturing particle boards and laminates. Their excellent adhesive properties and heat resistance make them an ideal choice for these applications.

Surface Coatings: The chemical and solvent resistance of melamine-formaldehyde resins makes them highly suited for surface coatings in various industries, including automotive and aerospace. They also find their use in decorative laminates, thanks to their hardness and non-porous characteristics.

Textiles: The textile industry also uses amino resins to improve the wrinkle resistance of fabrics. They often use them as cross-linking agents to create crease-resistant finishes.

Electrical Appliances: Melamine-formaldehyde resins, known for their excellent electrical insulation properties, are best for manufacturing electrical appliances.

Adhesives and Binders: Amino resins, especially urea- and melamine-urea-formaldehyde, are powerful adhesives, and various industries use them for this property, including woodworking and packaging.

Innovations in Amino Resin Production

Innovations in amino resin production have made the process more efficient, less costly, and more environmentally friendly in recent years. Advancements in catalyst technology have made it possible to control the reaction process precisely, resulting in high-quality resins with improved performance characteristics. Nanotechnology is also playing a role, with nanostructured amino resins showing enhanced properties, including superior strength and improved heat resistance.

Another innovation is the development of bio-based amino resins, derived from renewable resources such as plant-based materials, aiming to reduce our dependence on fossil fuels. These bio-based resins are gaining popularity as they promise sustainability without compromising the resins’ quality and performance.

These innovations in amino resin production not only enhance the properties and applications of these versatile materials but also open new avenues for research and development in the industry.

Market Outlook and Growth Potential for Amino Resins

The market for amino resins is on an upward trajectory, fueled by an escalating demand across various industries such as construction, automotive, textile, and electrical appliances. Technavio, a leading global technology research and advisory company, projects that the global amino resins market will grow at a Compound Annual Growth Rate (CAGR) of over 7% during the forecast period.

The increasing demand for particle boards and laminates in the construction and interior design sectors is one of the key driving forces of this growth. Technavio also expects the surge in various construction projects worldwide, coupled with the rising trend of interior decoration and furnishing, to propel the demand for amino resins.

The automotive industry is another significant consumer of amino resins, particularly melamine-formaldehyde resins, which they use extensively in their surface coatings and finishes. The automotive sector’s continuous growth, coupled with the rising demand for high-quality, durable coatings, further augments the market growth.

Additionally, many anticipate greater market growth due to innovations in the production of amino resins.These advancements not only address environmental and health concerns but also enhance the performance characteristics of resins, thereby expanding their application potential.

Understanding the versatility of amino resins is the first step in seeing the bigger picture as to where new advancements can take us. Analyzing the different applications currently available to us can open new ideas and windows to gain some perspective of where it can go in the future.

At Capital Resin Corporation, we pride ourselves on being one of the leading resin manufacturers in the industry. Our commitment to quality, innovation, and customer service has positioned us as a trusted partner for businesses worldwide. Reach out to us if you want to leverage the versatility of amino resins for your next project. We’ll explore how our advanced resin solutions can help drive your business’s success. Don’t settle for less! Choose Capital Resin Corporation, where excellence is our standard. Contact us anytime to learn more about the products and services we offer.