Efficiency and cost-effectiveness are top priorities for industries reliant on chemical manufacturing. Enter chemical process catalysts as essential tools for achieving both.

These catalysts facilitate reactions, reduce the energy required, and streamline production processes. Beyond their functional advantages, they also contribute to significant cost savings. This guide teaches you all about the cost savings of chemical process catalysts so you can understand how these savings emerge and how to leverage the benefits of catalysts.

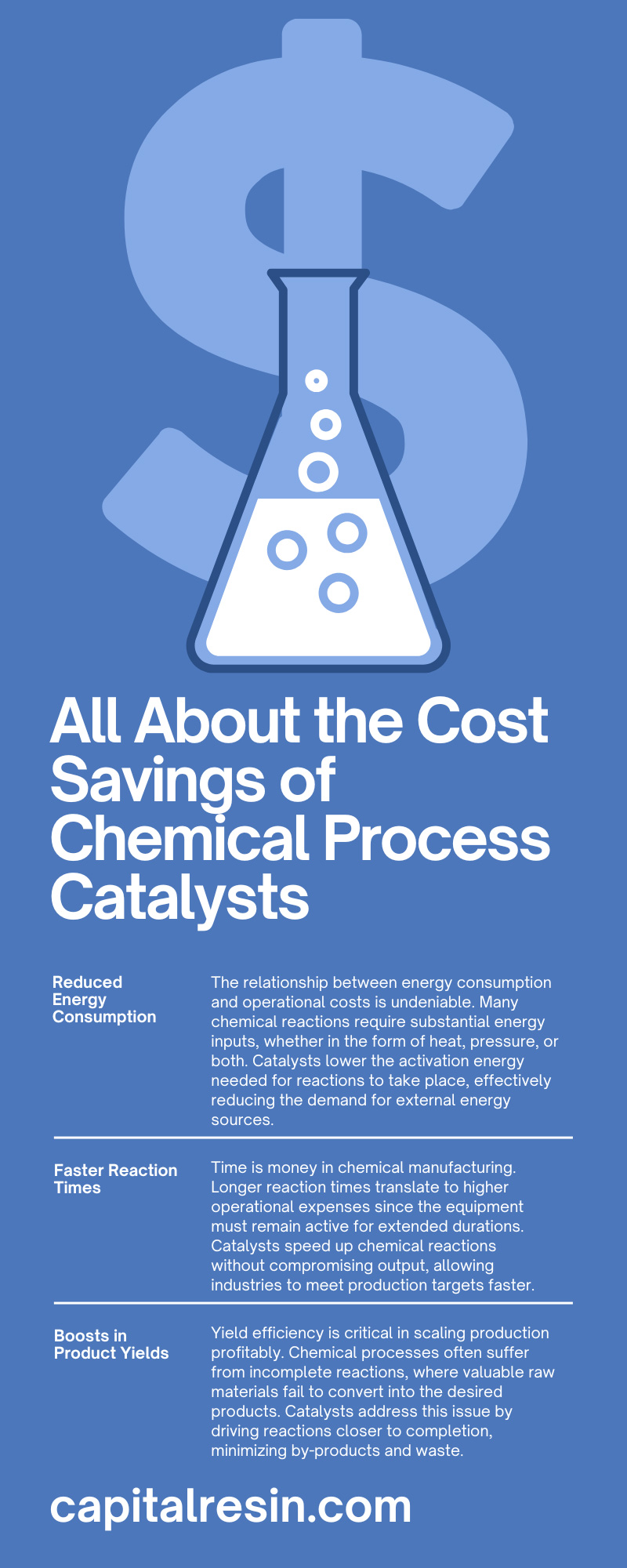

Reduced Energy Consumption

The relationship between energy consumption and operational costs is undeniable. Many chemical reactions require substantial energy inputs, whether in the form of heat, pressure, or both. Catalysts lower the activation energy needed for reactions to take place, effectively reducing the demand for external energy sources.

For example, ammonia production through the Haber-Bosch process depends heavily on catalysts. The reaction between hydrogen and nitrogen to form ammonia occurs at high temperatures and pressures.

With the right catalyst, manufacturers can achieve the same output at lower energy levels, resulting in reduced utility costs. When calculated across the scale of an industrial facility, the savings in energy can amount to millions annually.

Faster Reaction Times

Time is money in chemical manufacturing. Longer reaction times translate to higher operational expenses since the equipment must remain active for extended durations. Catalysts speed up chemical reactions without compromising output, allowing industries to meet production targets faster.

Take the case of pharmaceutical production, where synthesizing active ingredients often involves multiple reaction stages. Catalysts shorten the time required for each reaction stage, enabling companies to produce higher volumes within a shorter cycle.

Catalyst manufacturing experts, such as our team at Capital Resin Corporation, can provide the catalysts your business needs to complete timely and accurate chemical reactions and applications. With our products manufactured in compliance with industry standards, you can achieve expedited production timelines that save on labor and energy costs and enhance overall supply chain efficiency.

Boosts in Product Yields

Yield efficiency is critical in scaling production profitably. Chemical processes often suffer from incomplete reactions, where valuable raw materials fail to convert into the desired products. Catalysts address this issue by driving reactions closer to completion, minimizing by-products and waste.

Consider petrochemical processes, where fractions of crude oil undergo conversion into gasoline, diesel, and other outputs. Using advanced catalysts, refineries achieve higher yield percentages for desirable products, reducing feedstock waste. This improvement directly impacts profitability by maximizing the value extracted from raw materials.

Less Waste, Lower Disposal Costs

Chemical waste disposal is environmentally sensitive and costly. Stricter regulations mandate that companies manage their waste responsibly, often incurring significant expenses for waste treatment and disposal. By enabling cleaner and more efficient reactions, catalysts contribute to lower waste production.

One notable example is polymer manufacturing. Catalysts allow for precision in polymerization, resulting in fewer defective by-products. The reduction in waste materials limits the need for extensive post-processing treatments and decreases the costs associated with environmental compliance.

Extended Equipment Lifespan

Industrial equipment experiences wear and tear over time, especially under harsh operating conditions. High temperatures, pressures, and corrosive environments all take a toll. Catalysts can mitigate some of these factors by facilitating reactions under milder conditions.

For instance, catalytic converters in automotive manufacturing operate at controlled temperatures to convert harmful gases into less toxic emissions. Reducing the intensity of operating conditions extends the useful lifespan of converters and other related machinery. On a broader scale, this principle applies to reactors, heat exchangers, and pipelines in chemical plants, lowering maintenance and replacement costs.

Raw Material Savings

Catalysts influence the reaction’s efficiency and improve selectivity. Selectivity refers to a catalyst’s ability to direct a reaction toward producing a specific product rather than multiple by-products. High selectivity ensures that a larger portion of raw materials undergoes direct conversion into the intended product.

For example, methanol and carbon monoxide serve as raw materials in the production of acetic acid. Modern catalysts enable the reaction to produce acetic acid efficiently with minimal side reactions, resulting in less consumption of starting materials. The reduction in raw material usage leads to significant cost savings over time.

Support for Sustainable Practices

Consider how these products contribute to sustainability initiatives when diving into the cost savings of chemical process catalysts, which often align with cost reduction strategies. Energy efficiency, waste minimization, and resource conservation are all areas where catalysis excels.

Green chemistry is one field benefiting from catalytic innovation. Processes designed with environmentally friendly catalysts avoid toxic intermediates or hazardous solvents, reducing the cost of clean-up operations. This dual impact of lowering environmental harm and costs aligns with growing consumer and regulatory pressures for sustainable practices.

Innovations in Catalyst Technology

Advancements in catalyst development continually push the boundaries of cost efficiency. Tailored catalysts are becoming increasingly popular, offering targeted benefits for specific industries. These custom solutions aim to fit the exact requirements of a chemical process, optimizing reaction speed, yield, and environmental compliance.

For instance, zeolite catalysts in petroleum refining improve octane levels in gasoline while reducing undesirable by-products. Similarly, enzyme catalysts in food processing enable faster production cycles with lower energy input. Such innovations demonstrate how precise design in catalysis equates to measurable savings.

Industry Examples of Cost Savings

Understanding the scale of savings associated with catalysts requires examining specific fields. For example, consider how the petrochemical industry relies heavily on catalysis for cracking long-chain hydrocarbons. Oil refineries can reduce processing costs by minimizing waste and increasing yields by using advanced cracking catalysts.

Another notable example comes from the fine chemicals sector. Catalysis streamlines the synthesis of specialty chemicals, reducing the production costs of items such as fragrance compounds or food additives. With enhanced reaction pathways and minimized impurities, manufacturers avoid extensive purification steps and improve profit margins.

Catalysis and Scaling Operations

Scaling production introduces challenges, particularly with ensuring consistent quality and efficiency across larger operations. Catalysts assist by making large-scale processes more manageable. The same principles of energy reduction, waste minimization, and yield improvement apply, but with amplified impacts at scale.

For this reason, chemical plants expanding capacity to meet rising demand benefit significantly from catalytic processes. For every additional ton of product manufactured, the overall cost savings compound, ensuring that scaling is efficient and profitable.

The Broader Economic Impact

Beyond individual manufacturers, the widespread adoption of catalysts influences global economic trends. Reduced production costs mean competitive pricing for end consumers, driving demand. Simultaneously, lower energy consumption and waste emissions contribute to broader societal benefits, such as cleaner air and decreased environmental remediation costs.

Chemical process catalysts represent an indispensable resource for industries seeking to balance operational efficiency with cost-effectiveness. By minimizing energy usage, maximizing yields, and curbing waste generation, they unlock savings across various stages of production. Catalysts present a reliable pathway for companies striving to elevate their competitive edge to boost profitability and sustainability.